May 5, 2025

AccurasprayHub: Leveraging AI and Machine Learning to Define and Optimize Process Windows in Thermal Spray Operations

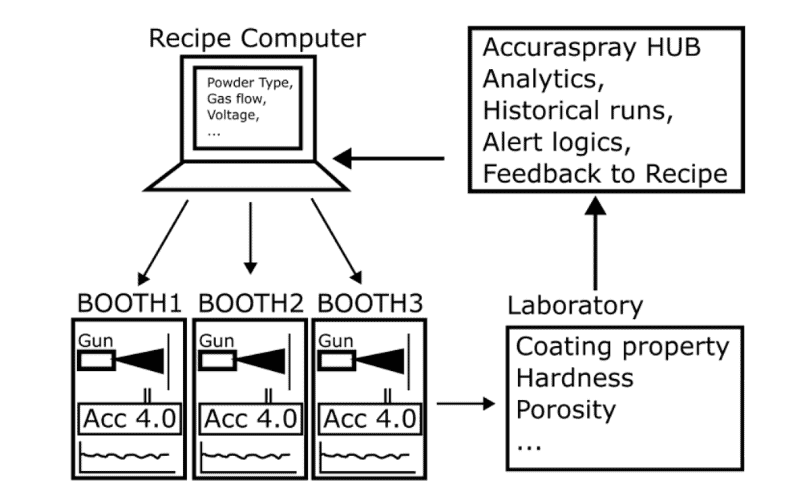

Consistent coating quality in thermal spray processes is challenging due to inherent complexity, operator-dependent controls, and evolving equipment conditions. While the use of advanced sensors for real-time process monitoring has grown, the effective integration of diverse data streams and the application of modern analytics remain limited. This paper presents the AccurasprayHub, a centralized data platform designed to harmonize booth parameters, in-situ plume measurements, maintenance schedules, and coating quality evaluations. By combining domain expertise with advanced analytics, including initial steps toward machine learning, the AccurasprayHub establishes robust datasets, identifies stable process windows, and provides proactive insights for process improvements. The approach is rooted in a realistic understanding of the complexities of thermal spray operations, emphasizing careful data construction, iterative refinement, and pragmatic adoption of informatics. Preliminary on-site trials with an aerospace industry partner have confirmed the platform’s value in improving process consistency and establishing a reliable foundation upon which more sophisticated AI-driven process control can be developed over time.

Paper by Tecnar Spray Sensors team, originally submitted to ITSC 2025 Conference

By J.N. Robert, D. Georgaris, J.F. Henri, D. Lessard, T. Garcin, A. Nadeau