Accuraspray 4.0:

Consistent thermal spray coatings – every run

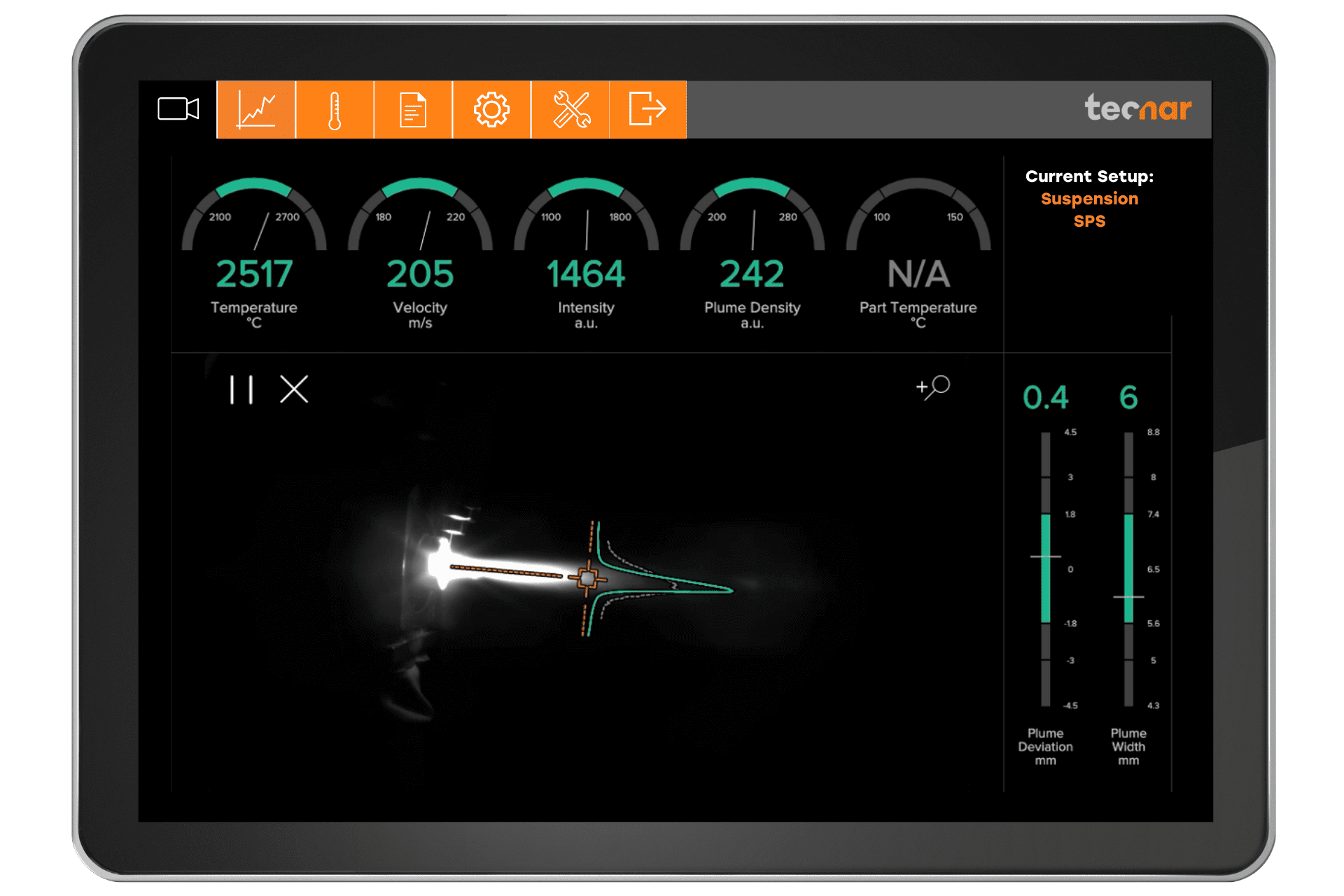

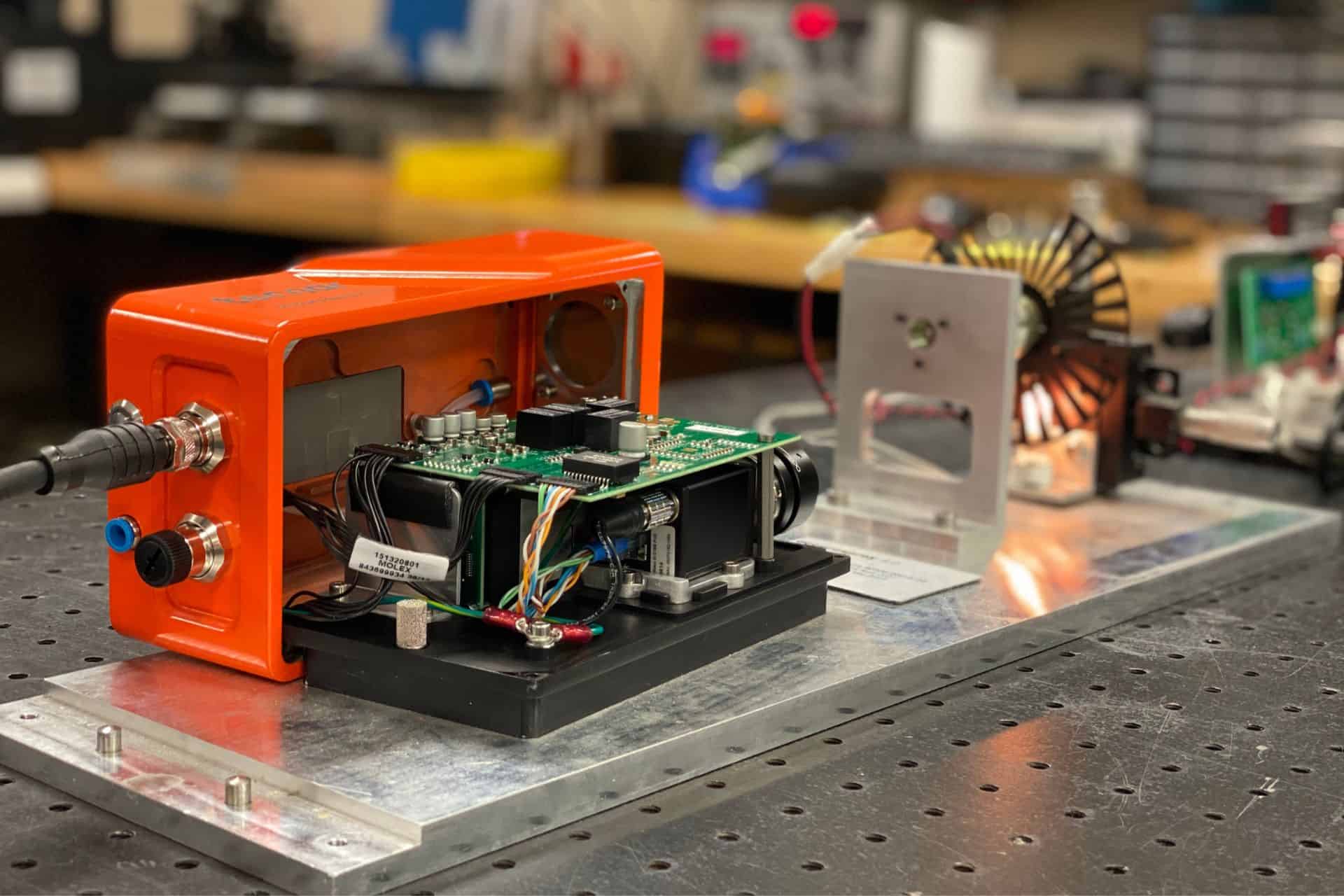

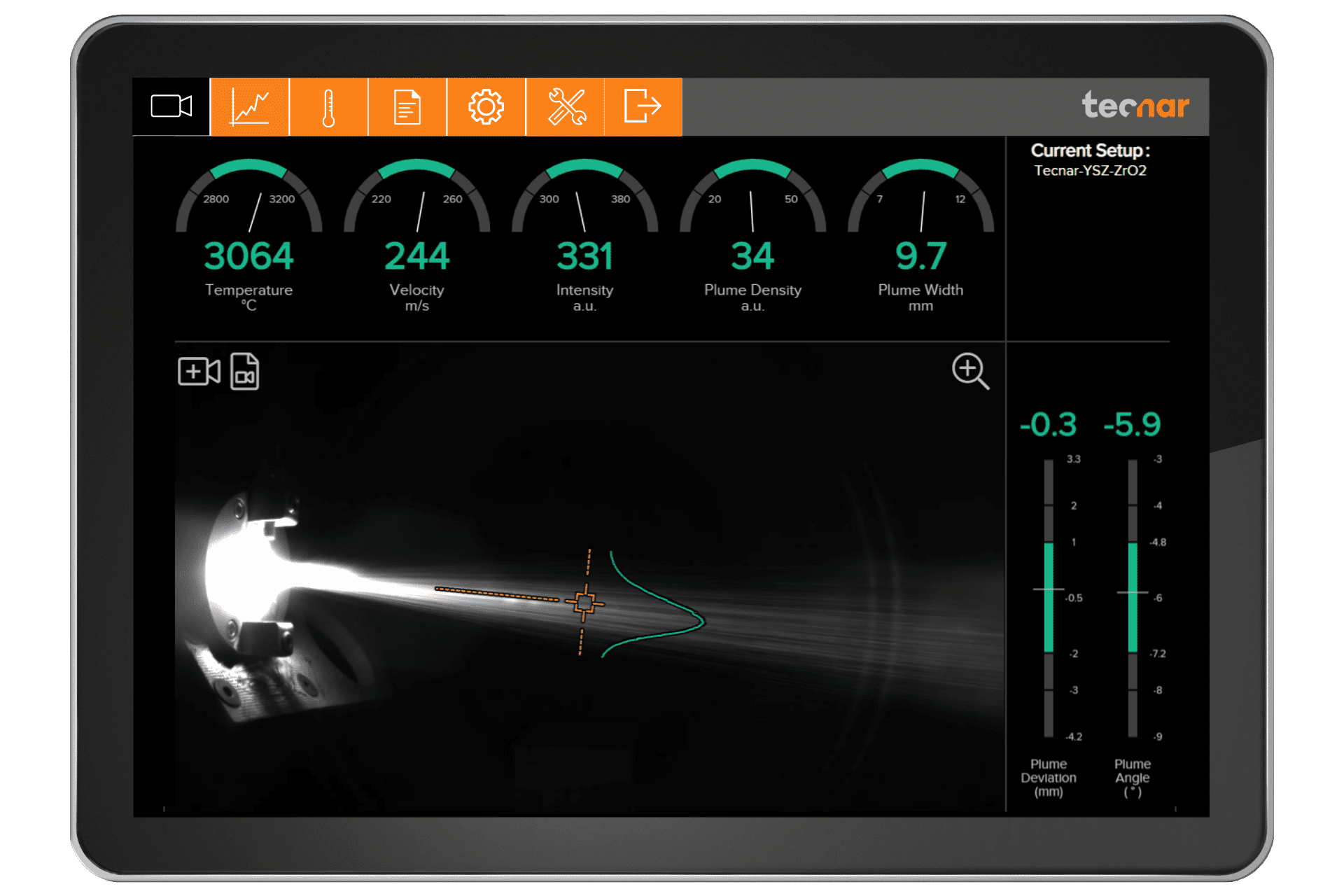

The Accuraspray 4.0 is an in-line thermal spray sensor that measures particle temperature & velocity, plume dimension, orientation, intensity & stability. It is used in more than 400 spray booths around the world for quality control, process development and set-up.

Talk to an expertMonitor what really matters

Consistent coatings come with consistent spray conditions

Our vision is simple: this is the industry’s watchdog for quality and consistency. That is why the fourth generation of the Accuraspray was built with one goal in mind: to democratize the use of spray sensors. It is dependable, versatile, easy to use and ready for a 100% automation of your spray booth.

Particle temperature

Particle velocity

Plume position

Plume angle

Plume intensity

Plume width

Plume density

Process stability

Substrate temperature (optional)

The Accuraspray 4.0 advantage

NEW – Process stability measurement

The notion of stability is of immense importance in thermal spray. Recognizing the importance of process stability in production, we have introduced a process stability measurement in the Accuraspray 4.0. This new, state of the art stability analysis tool develops bench-marks for acceptable measurement deviations to compare with real-time standard deviations. This allows for increased repeatability with higher confidence in your measurements.

Universal thermal spray sensor

The Accuraspray 4.0 is designed to be versatile and cost-effective across all spray processes.

It can characterize all thermal spray processes:

- Wire-Arc Spray

- Flame Spray

- Air Plasma Spray (APS)

- High Velocity Oxy-Fuel Spray (HVOF)

- High Velocity Air-Fuel Spray (HVAF)

- Suspension Plasma Spray (SPS)

- Vacuum plasma spray (VPS)

- Low-pressure plasma spray (LPPS)

- Plasma transferred wire-arc (PTWA)

The operator can easily switch from monitoring one process to another with just a click of Accuraspray’s web-based UI. High-level integrations of the sensors can also be performed using the unit’s HTTP API.

Best accuracy of the industry

The measurement principle of the Accuraspray is entirely independent of the nature of the process it’s monitoring. The readings are certified using filtering algorithms so that any displayed number can be trusted. All the available metrics provided by the Accuraspray are factory calibrated on proprietary NIST traceable calibration stations that simulate the exact temperature, intensity and velocity ranges expected in the field.

Absolute repeatability

For this fourth generation of the product, we envisioned that the Accuraspray 4.0 would spread the use of sensors for process parameters transfer, parameter development and process consistency to each and every booth in the world. We believe that building trust in the product’s consistency is the key to democratizing the use of sensors.

Save time

- Faster spray parameter development and spray equipment optimization

- Easy parameter transfer from booth to booth and between spray facilities

- Quickly qualify new feedstock lots and hardware

- Validate spray equipment performance after maintenance.

Industry 4.0 ready

Ready for automation

Simple and easy to use, the Accuraspray 4.0 features a web-based, user interface making the information available by more than five viewing devices simultaneously. It can also be connected to the spray cells robot controller to automate the measurement before each spray session.

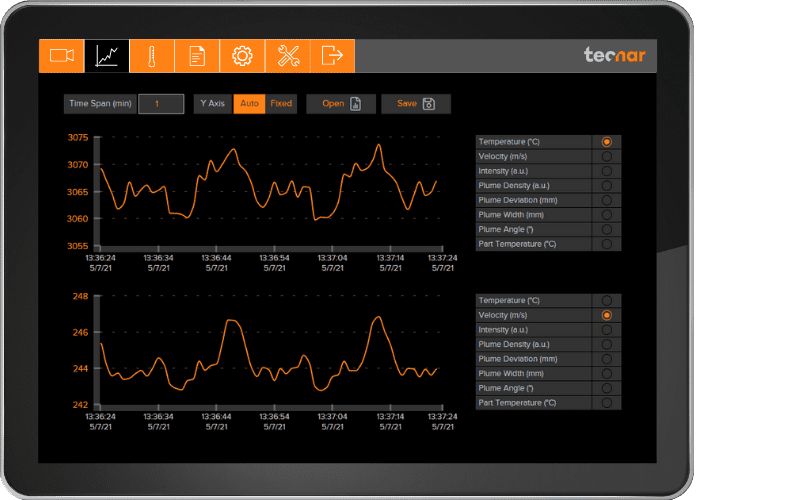

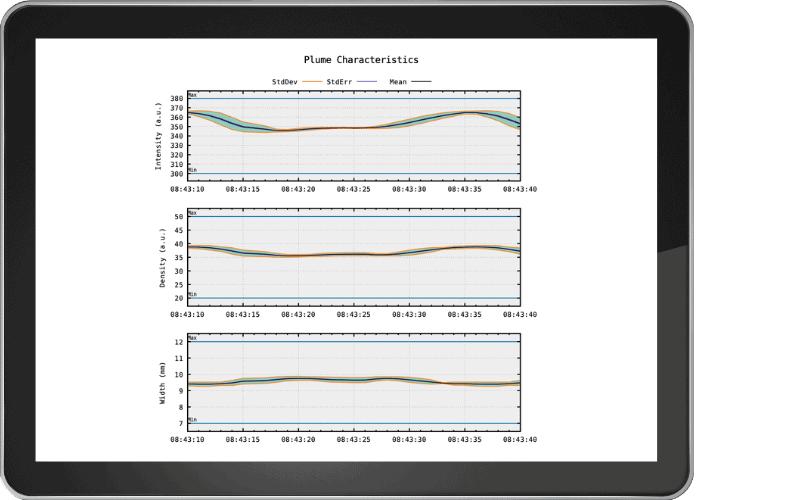

Strip chart displays

The evolution of all measurements over time is visualized on intuitive strip chart displays.

Production reports

Production reports are generated with a single click in the user interface or through digital I/O.

Spray conditions

The Autoset feature automatically adjusts all important Accuraspray 4.0 operating parameters according to spray conditions.

Available option

Substrate temperature control with infrared pyrometer integration

The substrate temperature is essential for many coating properties like residual stress and adhesion. To ease the integration of an additional sensor and facilitate the control of the substrate temperature, the Accuraspray 4.0 offers an optional non-contact IR pyrometer. Operating in the temperature range of 0 to 500°C, it seamlessly integrates into the system, enhancing substrate temperature control during both surface preparation and spraying processes.

Once connected to the Accuraspray 4.0 head, the pyrometer consistently streams real-time readings. These readings are instantly accessible through the Accuraspray user interface and are also securely stored in the system’s database for comprehensive monitoring and analysis.

Integrating the Accuraspray 4.0 into your process

It’s important that our clients understand how easy it is to integrate the Accuraspray 4.0 into their quality process. We’ve divided this into the following five steps:

Ongoing support and warranty

Tecnar takes pride in offering the best engineering warranty and support in the business so you can rely on Accuraspray 4.0 technology for years to come.

But don’t just take our word for it… take it from our customers.

Technical specifications - Accuraspray 4.0

Measurements

Particle temperature range

≥1000 °C at 3% accuracy

≥1832 °F at 3% accuracy

Particle velocity range

5-1200 m/s at 2% accuracy

15-4000 ft/s at 2% accuracy

Plume intensity

5% accuracy

Plume width and position

±0.6 mm accuracy

±0.02 in. accuracy

Plume angle

0.2 degree accuracy

Substrate temperature pyrometer

0-500 °C

32-932 °F

Process stability

Automatic instability detection

Measurement area information

Working distance

200 mm

7.87 in.

Temperature and velocity measurement area with cylindrical lens (default)

3.4 mm x 25 mm = 85 mm²

0.13 in. x 1 in. = 0.13 in.²

Temperature and velocity measurement area without cylindrical lens

⌀3.4 mm = 9 mm²

⌀0.13 in. = 0.014 in.²

CMOS camera field of view

450 mm

17.7 in.

Plant supplies

Power requirements

120/230 VAC Auto-Switch 50/60Hz 1.5/1.5A

Air supply

1.35-2 bar, during spray operations

20-30 psi, during spray operations

Positioning bracket

Refer to mechanical drawing in manual

Dimensions and weight

Sensor head

190 mm x 110 mm x 62 mm

1.8 kg

7.5 in. x 4.3 in. x 2.5 in.

4 lb

Controller

230 mm x 230 mm x 102 mm

5.6 kg

9 in. x 9 in. x 3.9 in.

12 lb

Total weight

7.4 kg

16 lb

Shipping specifications

Total dimensions

570 mm x 380 mm x 260 mm

22.4 in. x 15 in. x 10.2 in.

Total weight

12 kg

26.5 lb

Sensor head dimensions

210 mm x 170 mm x 260 mm

8.3 in. x 6.7 in. x 10.2 in.

Sensor head weight

3 kg

6.61 lb

Interested in the Tecnar Accuraspray 4.0?

Leave your details so our experts can contact you. Our team will answer all your questions and suggest the best solution for your needs.