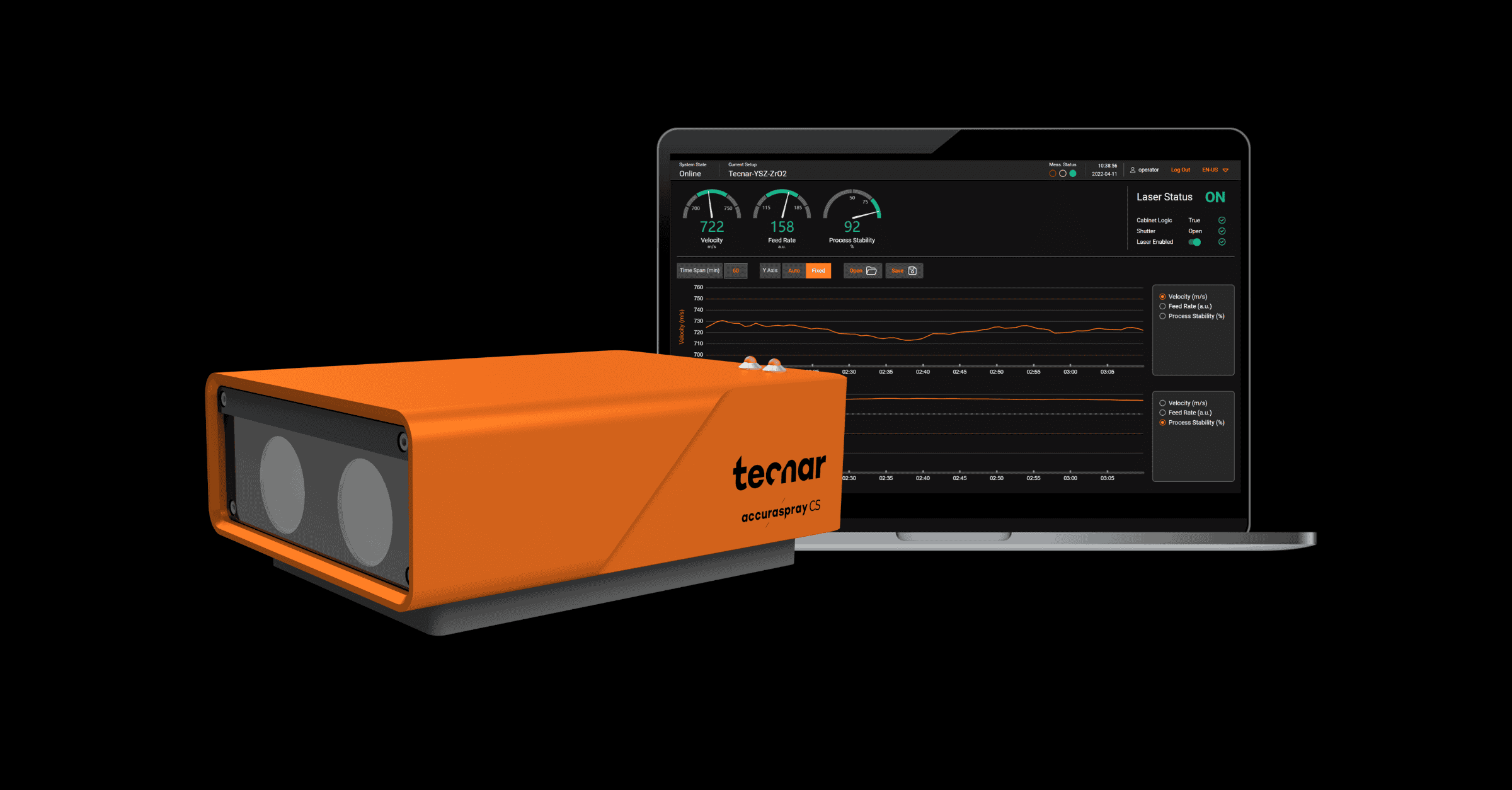

Accuraspray CS:

Production-friendly cold spray sensor

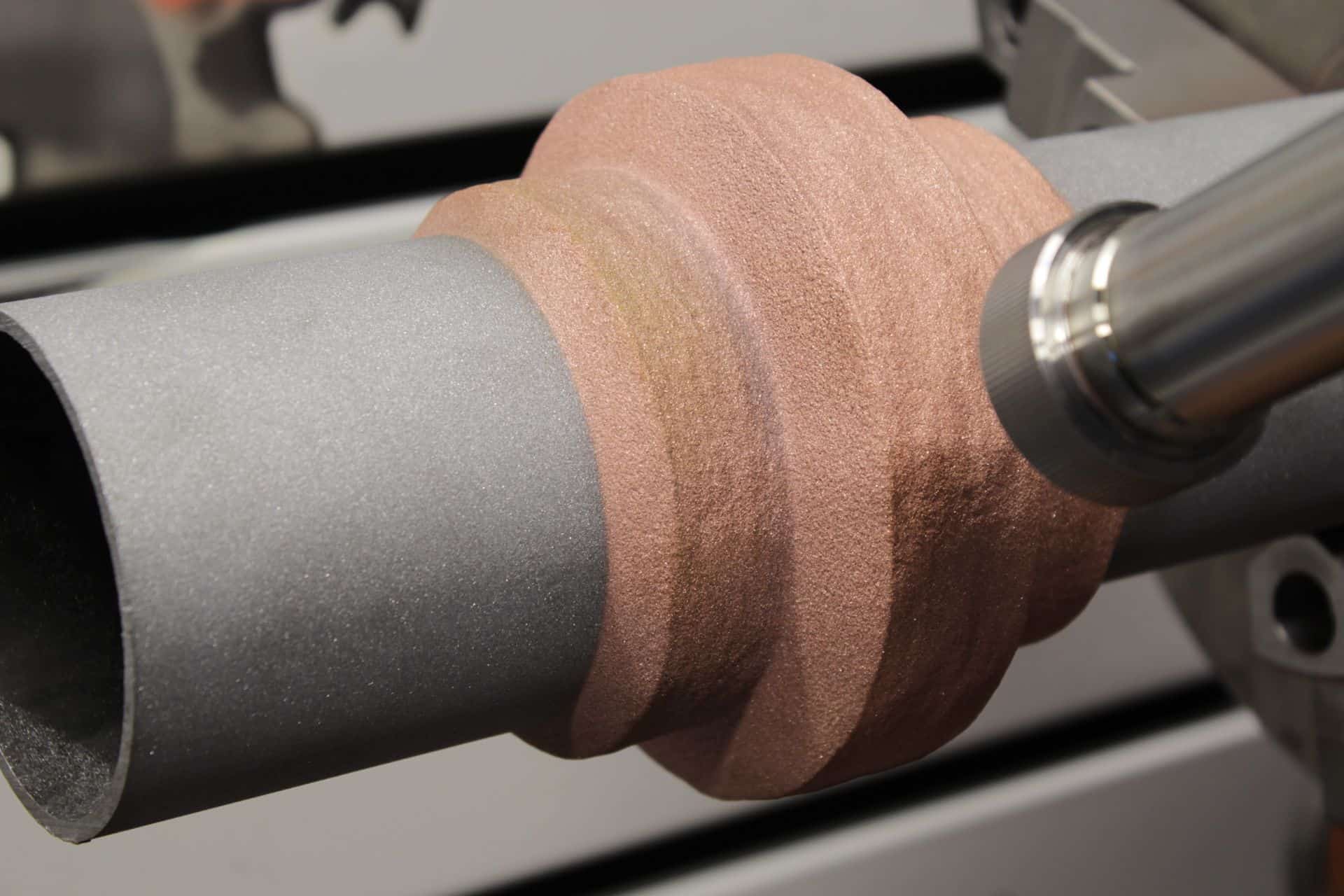

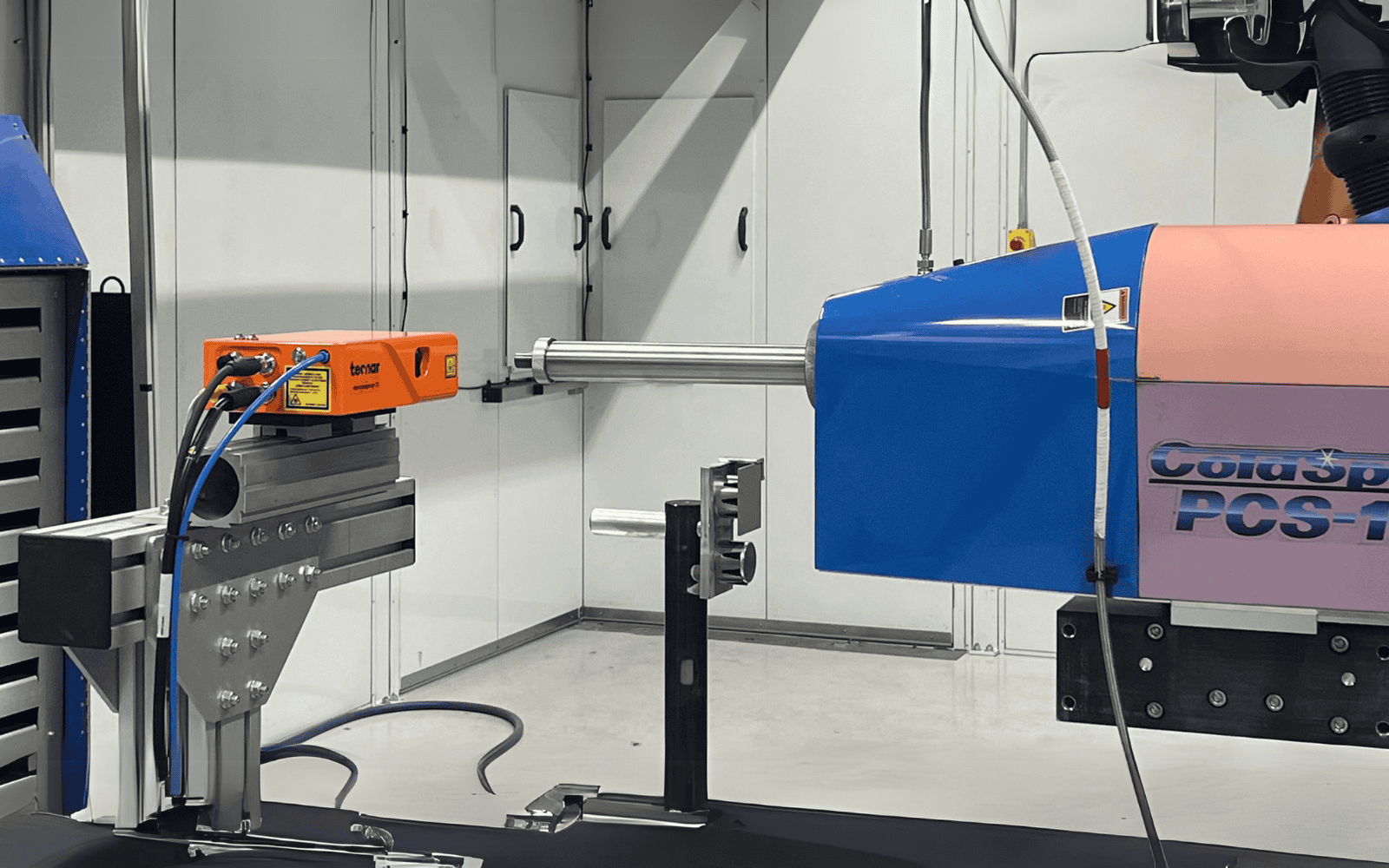

The Accuraspray CS is an in-line cold spray sensor that measures in-flight particle velocity and feed rate. This is an easy-to-use cold spray sensor to monitor daily quality control, process development, and setup transfer.

Talk to an expertMonitor your cold spray process

Control your process to control your coatings

The vision behind the Accuraspray CS is to make cold spray diagnostics accessible to all. That’s why we created an easy-to-use, dependable and affordable sensor for all cold spray shops. Don’t leave things to chance. Control your spray conditions to achieve repeatable coatings, every run.

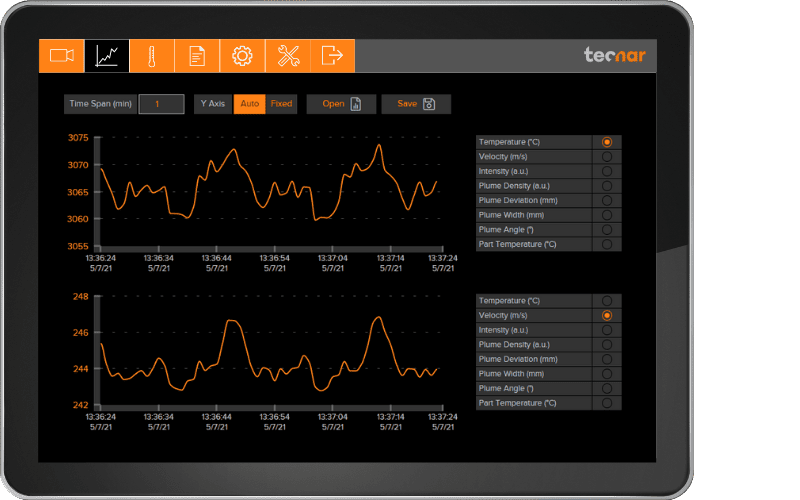

In-flight particle velocity

Relative feed rate

Process stability

Substrate temperature (optional)

The Accuraspray CS advantage

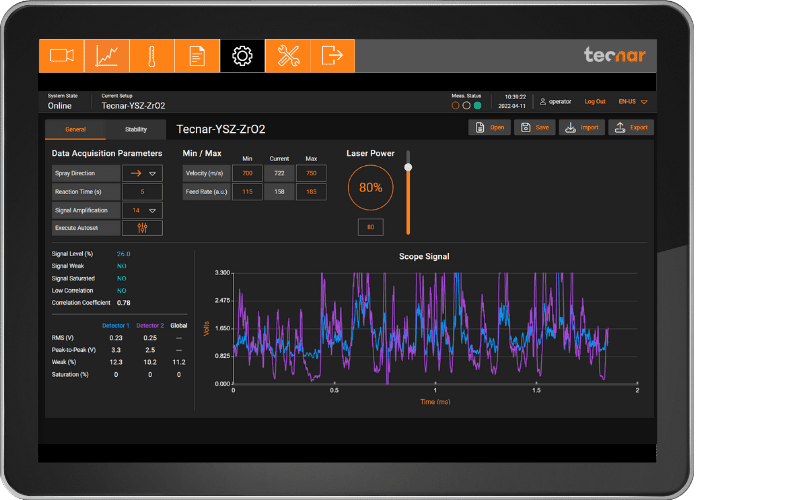

Achieve critical velocity

Cold spray processes are very sensitive to particle velocity. Achieving critical velocity is key to maximizing deposition efficiency and ensuring good coating adhesion. Monitoring the real-time in-flight velocity can help production managers attain maximum spray time efficiency and coating consistency.

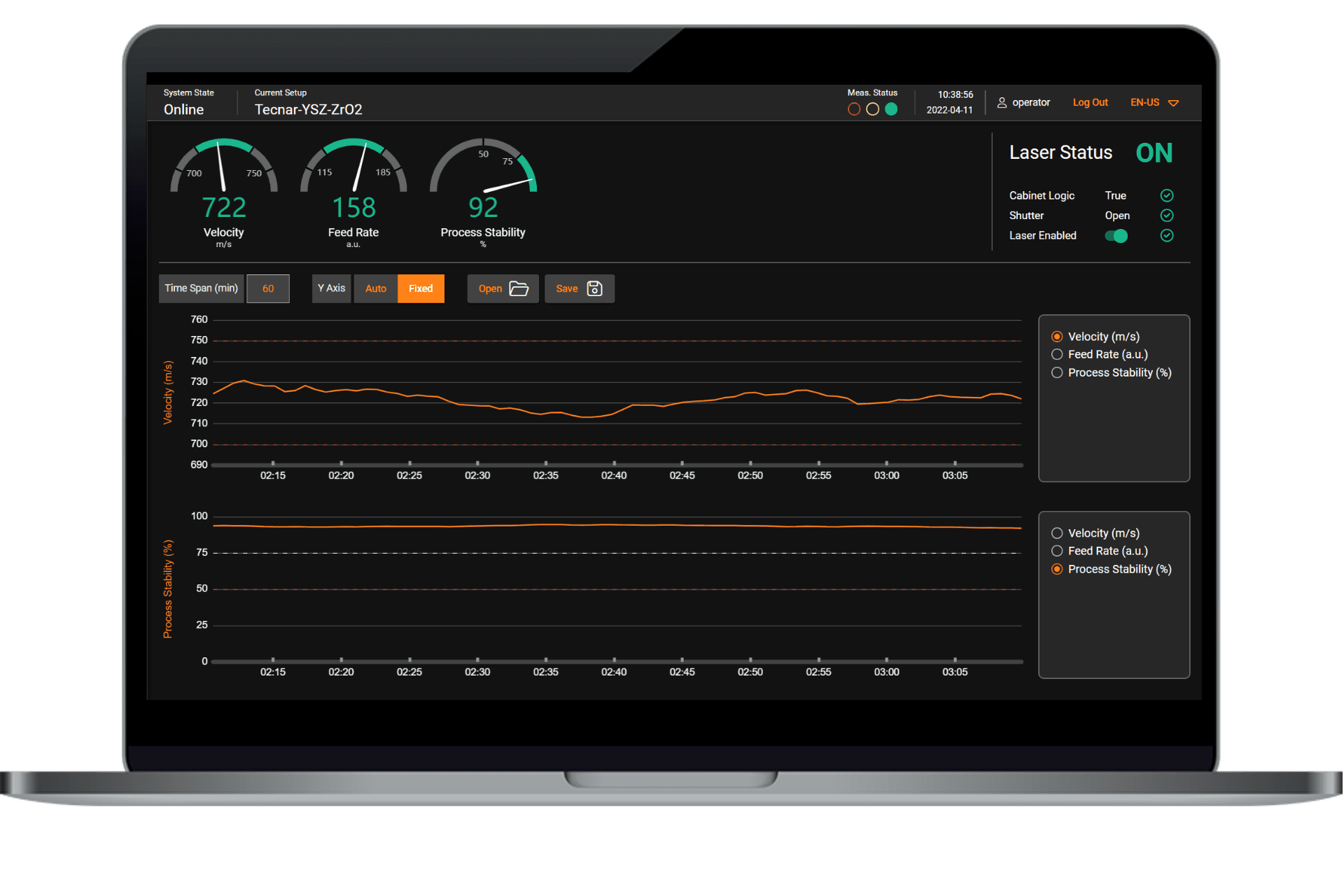

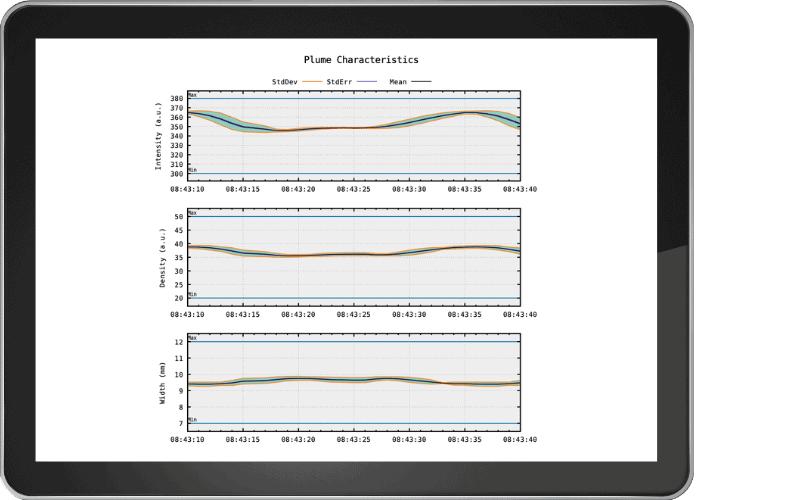

Process stability measurement

Since stability is crucial in spray processes, the Accuraspray CS features a new process stability measurement. This state-of-the-art stability analysis tool sets benchmarks so operators can compare acceptable parameter deviations with real-time standard deviations. This results in increased repeatability and greater confidence in your measurements.

Best accuracy in the industry

The Accuraspray CS was built on the consistent, easy-to-use Accuraspray 4.0 platform, the benchmark for spray diagnostics in production environments. The Accuraspray CS may be a new product at Tecnar, but it capitalizes on decades of engineering in the Accuraspray family.

The velocity measurements are factory calibrated using a NIST traceable calibration bench to recreate the conditions experienced in the field and filtering algorithms display values you know you can trust.

Save time

- Quicker spray parameter development and process optimization

- Easy parameter transfer and replication from booth to booth

- Quicker equipment qualification for new guns and powders

- Quicker coating qualification due to no bad coating coupons

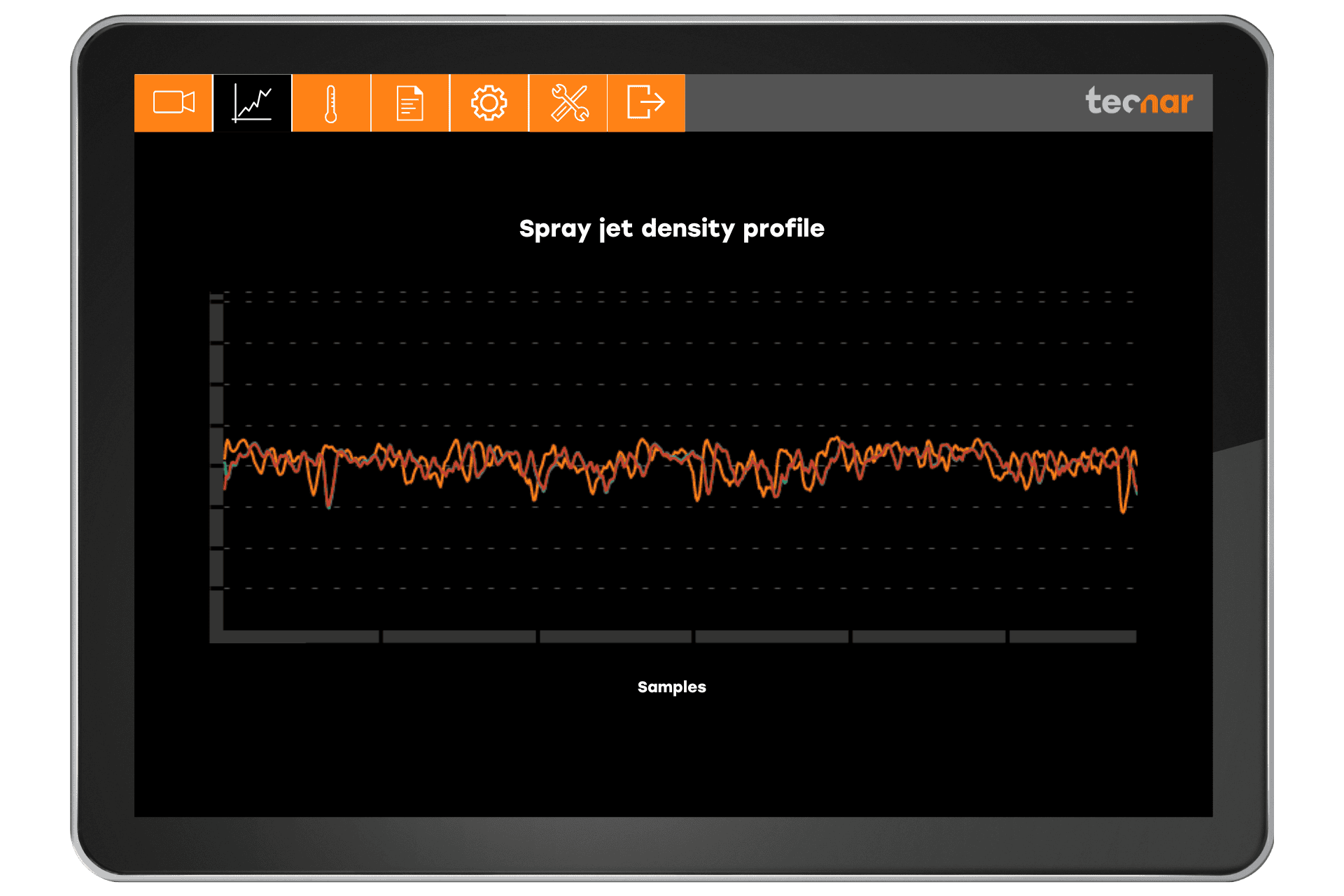

Live feed rate

The Accuraspray CS measures the light reflected by the particles in the spray jet so you can monitor the feed rate in real time. Predict clogging in the gun, nozzle wear or changing booth conditions by detecting swaying feed rate. The user can also set up correlations for the feed rate with preferred units (g/min or RPM) for a specific powder lot.

Industry 4.0 ready

You’re in control with the Accuraspray CS. It features a modern, web-based user interface, making it easy to access from any computer, anywhere and the interface can be viewed on multiple viewing devices simultaneously. Communication infrastructure via HTTP or external PLC makes full 4.0 booth integration possible, including communication with robots and Go/No Go decisions.

Strip chart displays

The evolution of all measurements over time is visualized on intuitive strip chart displays.

Production reports

Production reports are generated with a single click in the user interface or through digital I/O.

Setup files

The Autoset feature automatically adjusts all important setup parameters according to spray conditions.

Integrating the Accuraspray CS

It’s important that our clients understand how easy it is to integrate the Accuraspray CS into their quality process. We’ve divided this into the following five steps:

Technical specifications - Accuraspray CS

Measurements

Particle velocity range

5-1200 m/s at 2% accuracy

15-4000 ft/s at 2% accuracy

Relative feed rate

Normalized a.u.

Substrate temperature pyrometer

0-500 °C

32-932 °F

Process stability

Automatic instability detection

Measurement area information

Measurement area

⌀3.4 mm = 9 mm²

⌀0.13 in. = 0.014 in.²

Working distance

200 mm

7.87 in.

Laser characteristics

Laser wavelength

940 nm

Nominal laser power

20 W

Nominal power density

15.7 W/cm²

101 W/in²

Laser type

Class IV

Plant supplies

Power requirements

120/230 VAC Auto-Switch 50/60Hz 3/2A

Air supply

2.4 bar

35 psi

Positioning bracket

Refer to mechanical drawing in manual

Dimensions

Sensor head

205 mm x 149 mm x 62 mm

3.2 kg

8.1 in. x 5.8 in. x 2.4 in.

7.1 lb

Controller

400 mm x 400 mm x 200 mm

13.9 kg

15.7 in. x 15.7 in. x 7.9 in.

28.7 lb

HMI

238 mm x 110 mm x 126 mm

1.8 kg

9.4 in. x 4.3 in. x 5 in.

4 lb

Total weight

18.9 kg

41.7 lb

Shipping specifications

Total dimensions

610 mm x 610 mm x 770 mm

24 in. x 24 in. x 30 in.

Total weight

63 kg

139 lb

Interested in the Tecnar Accuraspray CS?

Leave your details so our experts can contact you.

Our team will answer all your questions and suggest the best solution for your needs.