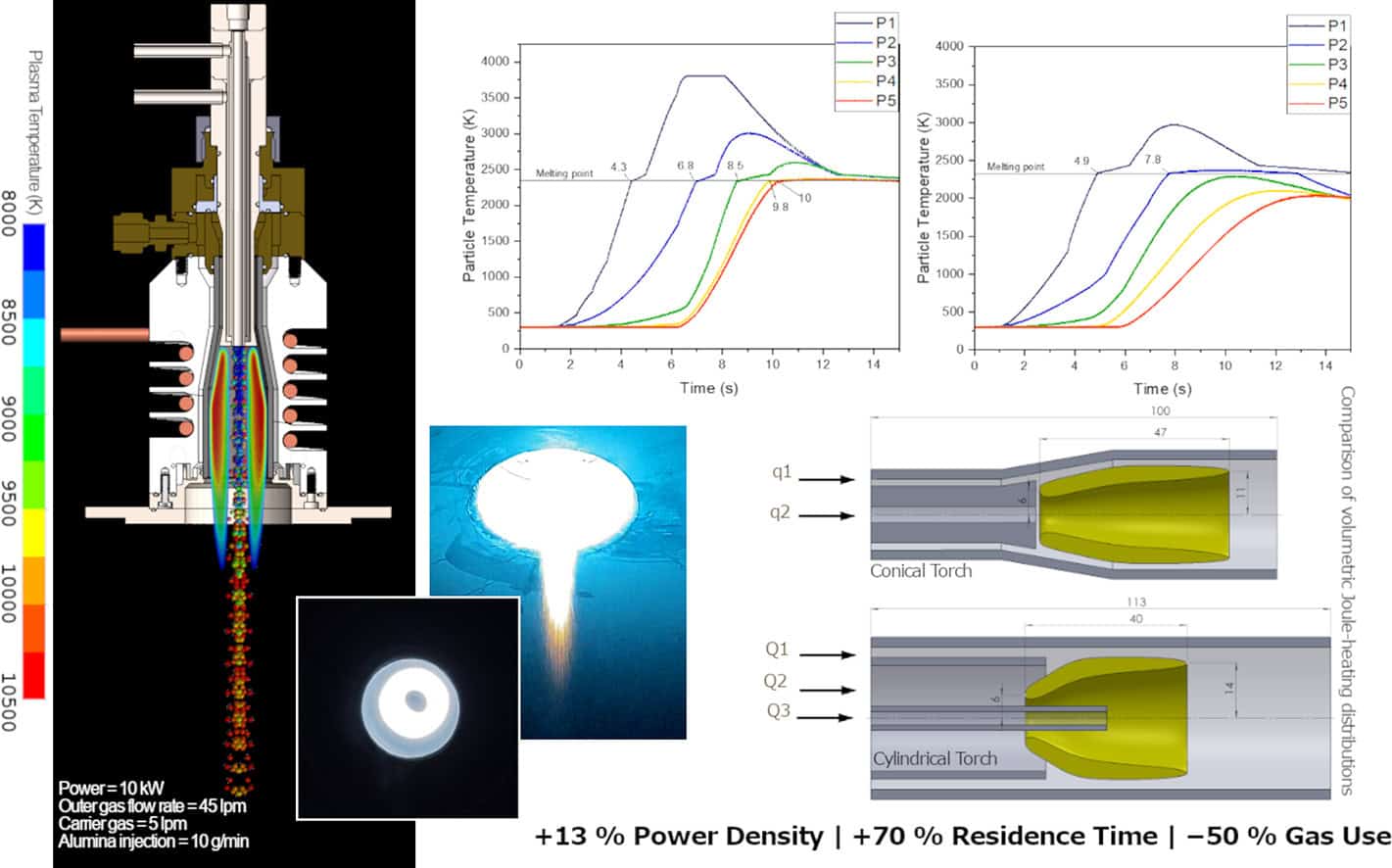

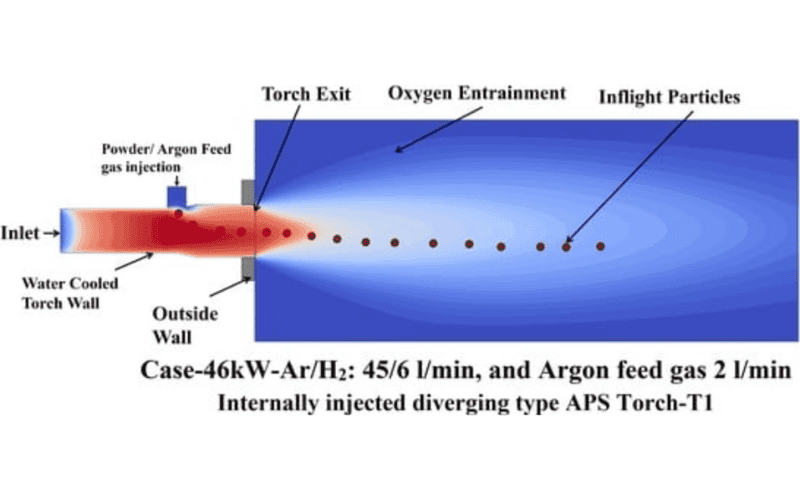

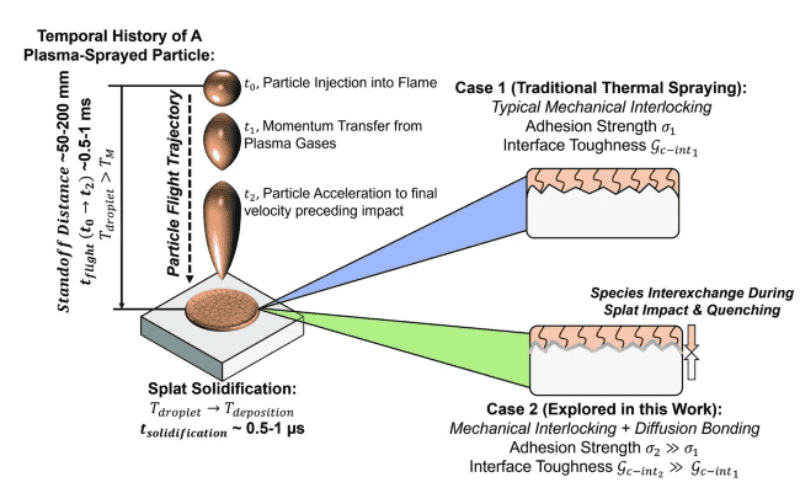

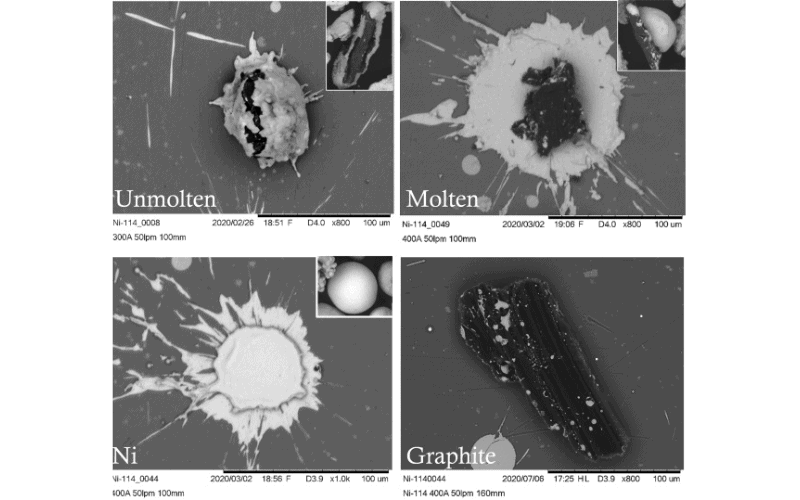

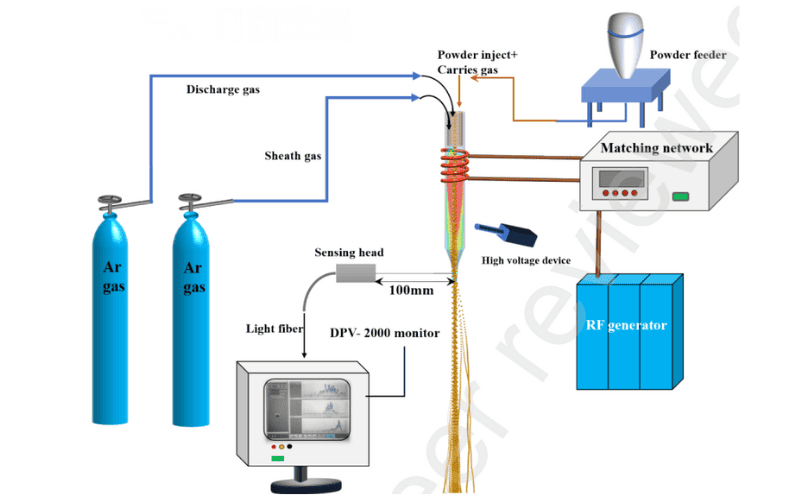

Radio-frequency inductively coupled plasma (RF-ICP) torches are widely used for high-temperature powder processing; however, conventional cylindrical designs distribute RF energy […]

Development And Experimental Validation Of A High-Power Conical RF-ICP Torch For Advanced Material Processing