Thermal barrier coating system (TBCs) prepared using the Air plasma spray (APS) method are widely recognized as the most prevalent […]

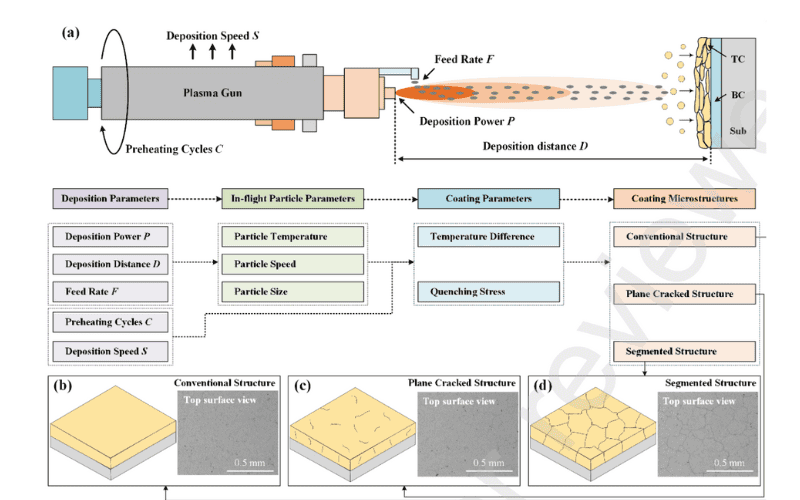

Influence of Deposition Parameters on the Formation of Surface Cracks in Segmented Aps-Tbcs

Thermal barrier coating system (TBCs) prepared using the Air plasma spray (APS) method are widely recognized as the most prevalent […]

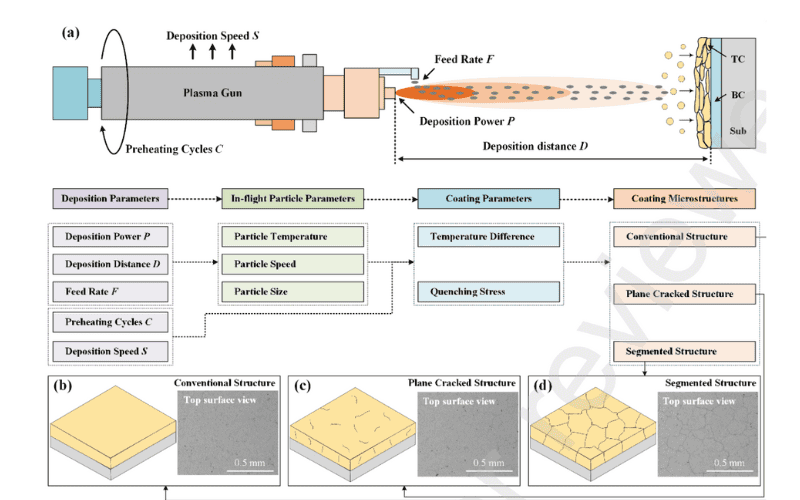

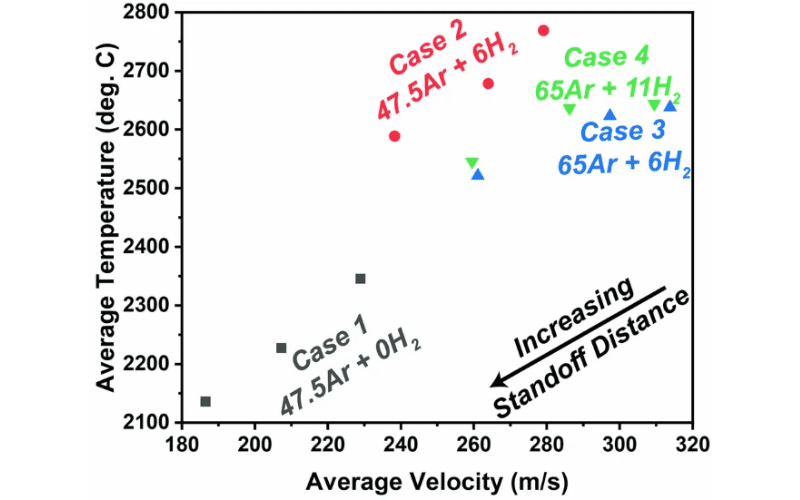

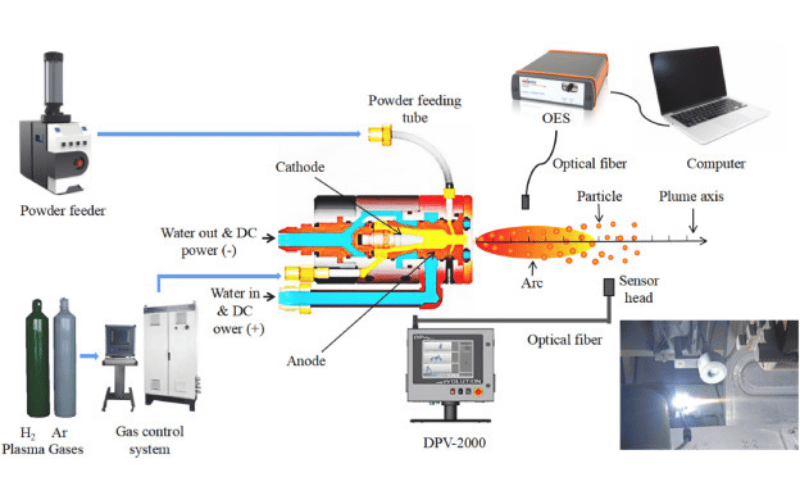

In plasma spraying, H2 or N2 is commonly added to the primary Ar plasma which may increase the specific enthalpy, […]

Aluminum alloys (Al) produced by fusion-based additive manufacturing techniques exhibit limited strength due to undesirable grain growth, porosity, and thermal […]

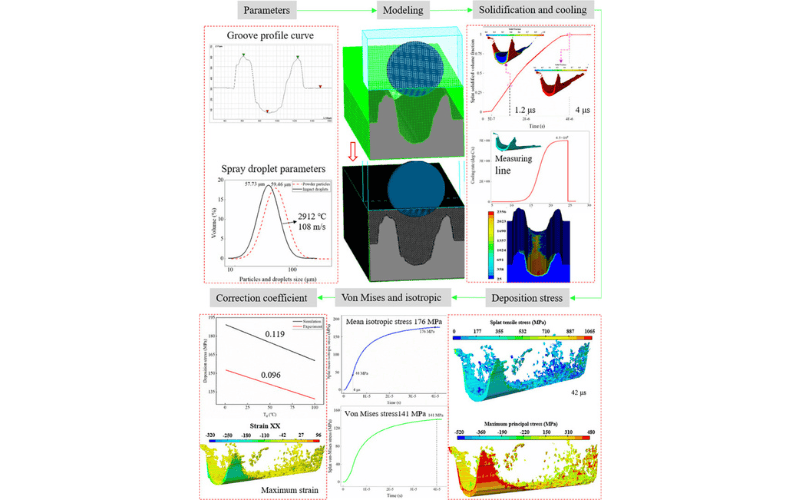

This study focuses on understanding the crucial phenomenon of deposition stress during the splat formation of plasma-sprayed droplets, which is […]

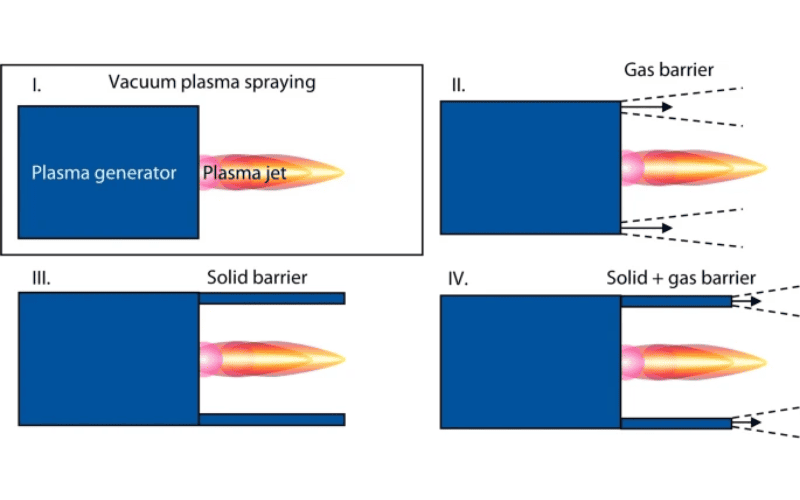

Plasma spraying is characterized by high flexibility, but has challenges of high energy consumption and oxidation of the metallic spray […]

Thermal spray deposition (specifically Atmospheric Plasma Spraying, APS) is a well-established surface coating technology with a broad scope of applications […]

In this study, the plasma torch is utilized for the preparation of highly pure ZrO2 from zircon (ZrSiO4). The incorporation […]

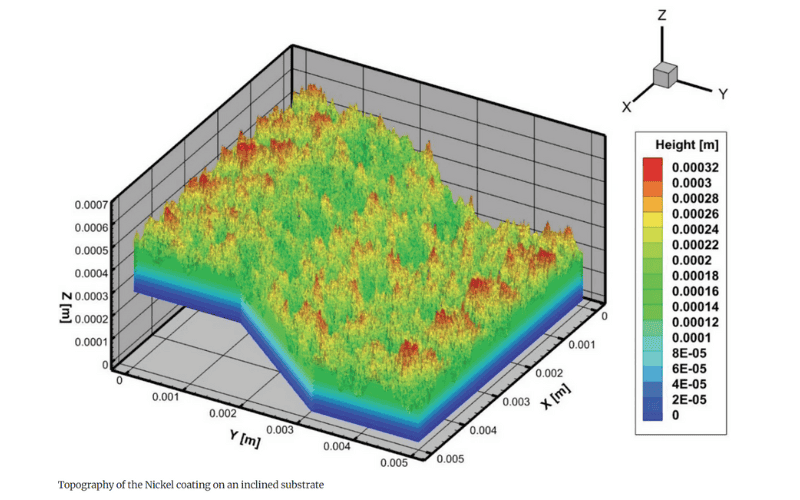

The main focus of this study is on simulation of coating formation on substrates with arbitrary shapes. For this purpose, […]

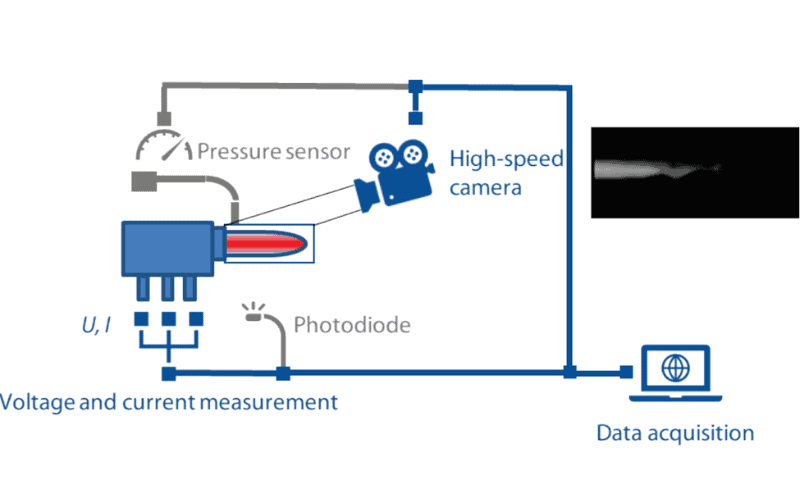

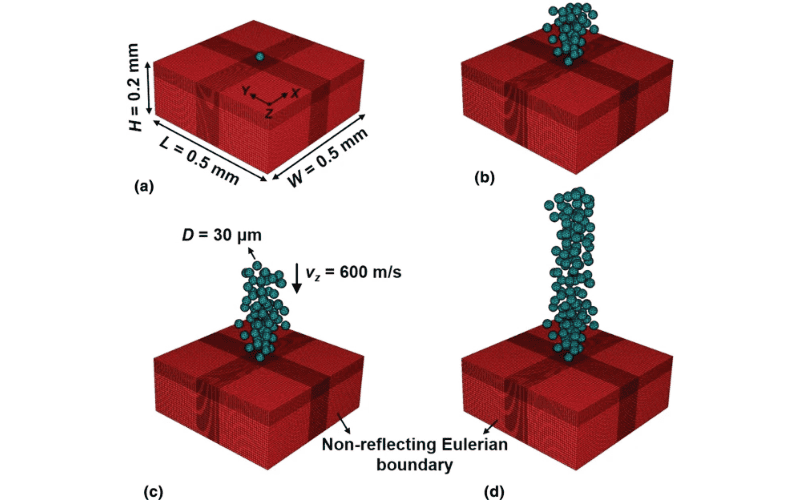

Residual stress is an important factor that affects the properties of cold spray coatings. The study performed 2D single-, 3D […]