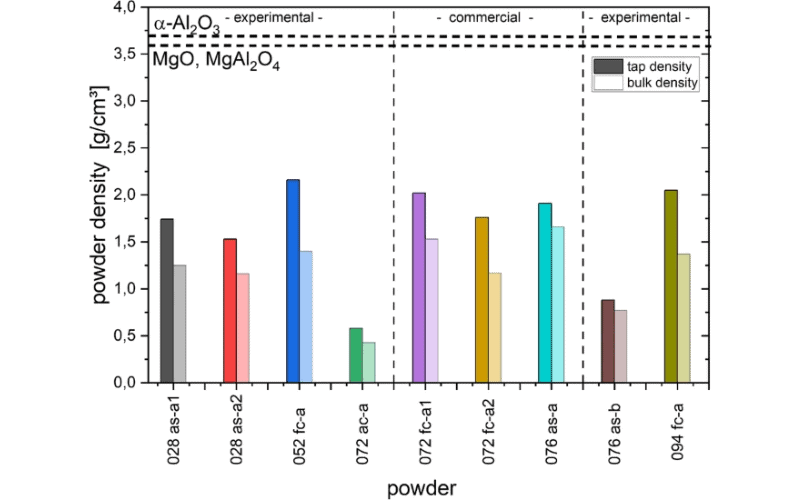

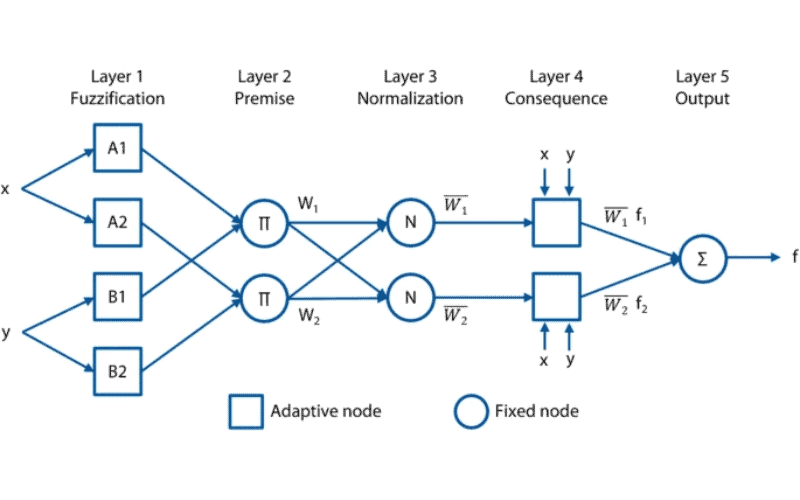

Nine commercial and experimental powders from the MgO/Al2O3 system have been investigated in the present project. The composition ranged from […]

Atmospheric Plasma Spraying of Different MgO/Al2O3 Feedstocks

Nine commercial and experimental powders from the MgO/Al2O3 system have been investigated in the present project. The composition ranged from […]

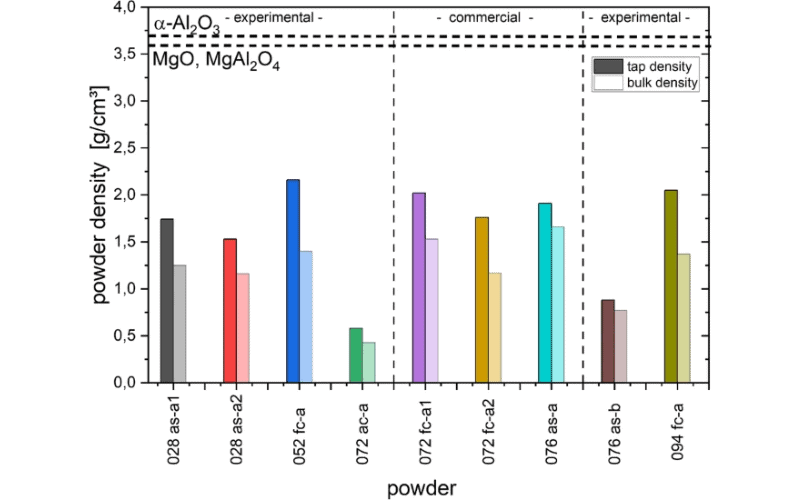

Thermal barrier coatings (TBCs) with high thermal strain tolerance and erosion resistance are strongly desired in gas turbine engines. Air […]

Deposition efficiency (DE) serves as a key performance indicator in plasma spraying, which is tailored by dozens of intrinsic and […]

The impact phenomena of high velocity micron-size particles, although commonly considered and described as detrimental in numerous engineering applications, can […]

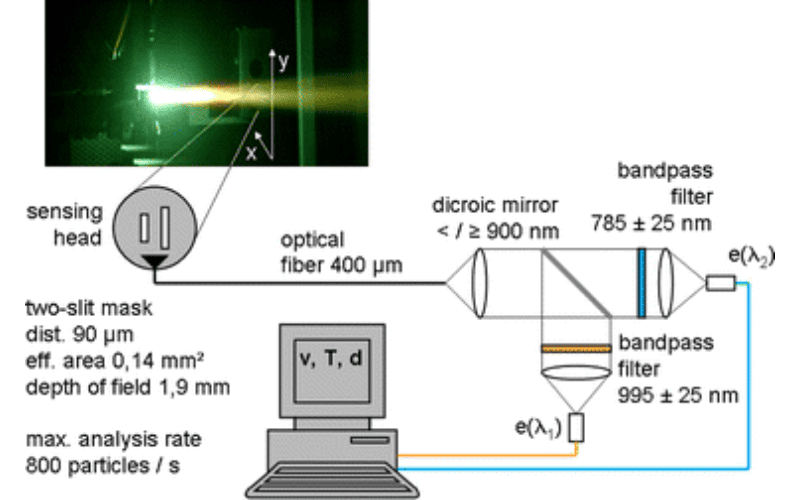

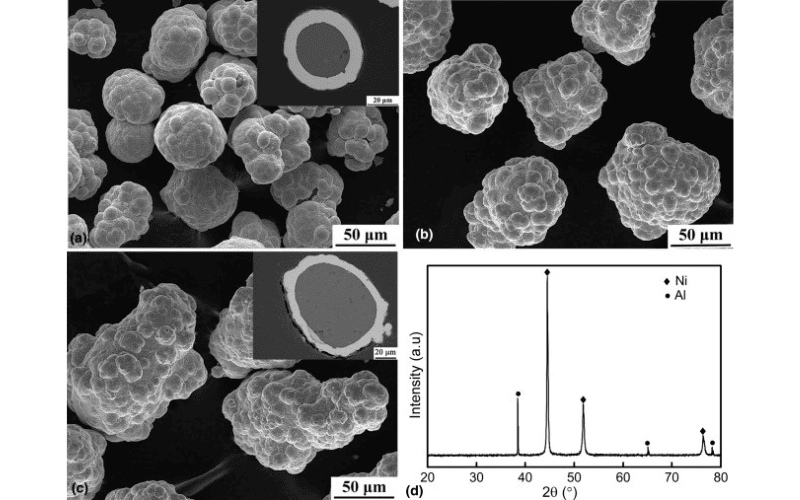

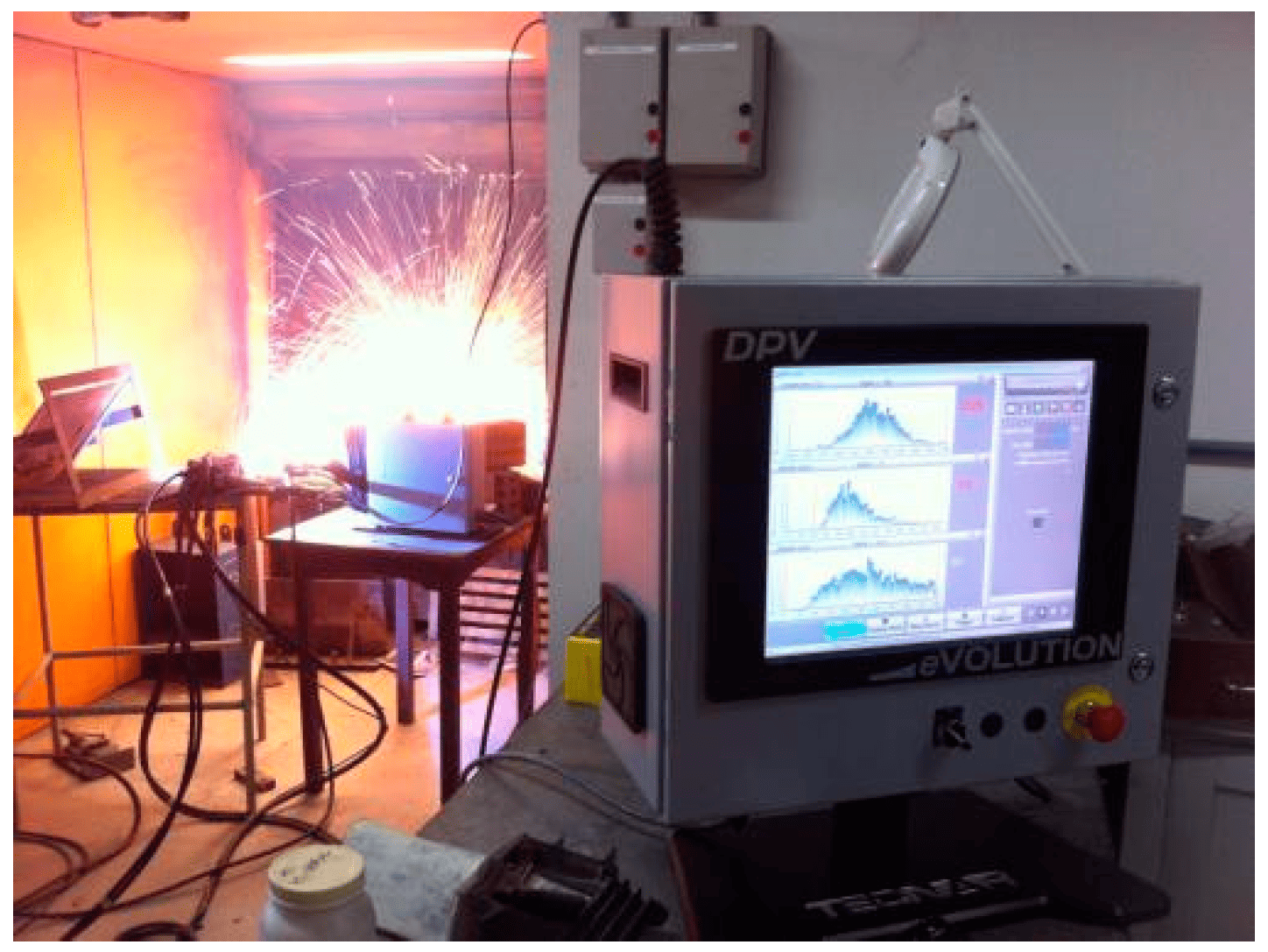

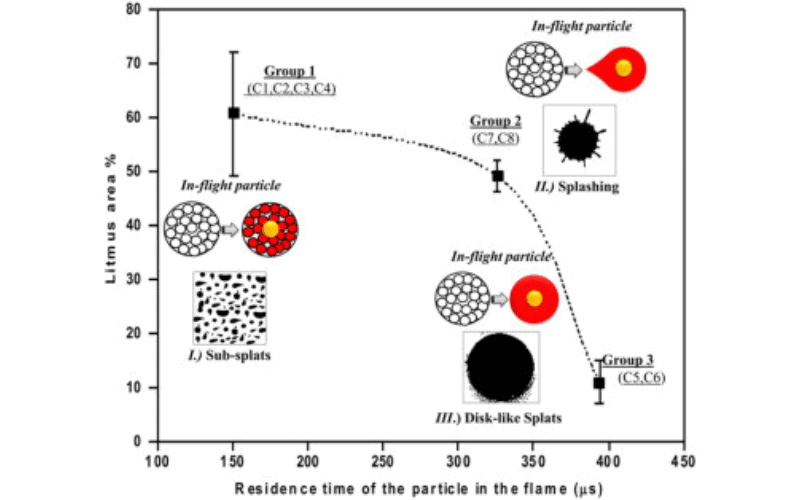

It was known for long that Ni-Al composite powders can be used to deposit self-bonding coating as a bond coat […]

Thermally sprayed coatings are employed for many purposes, as corrosion protection, wear resistance improvement, resistance to high temperatures, and others. […]

High-velocity oxygen fuel thermal spray stainless steel coatings are desirable for their excellent erosion resistance. However, the fabrication process can […]

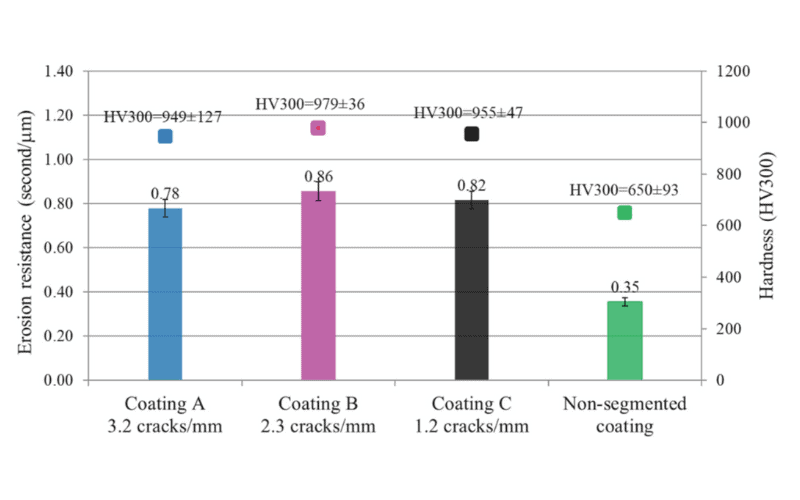

The first-of-its-kind use of the active learning (AL) framework in thermal spray is adapted to enhance the prediction accuracy of […]

The High-Velocity Oxy-Fuel (HVOF) technology has been widely used to deposit cermet, metals, and alloy coatings. However, the high temperature […]