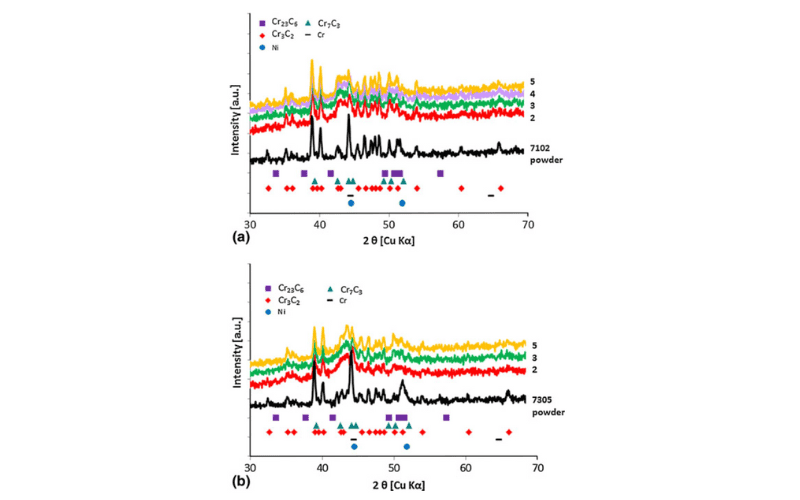

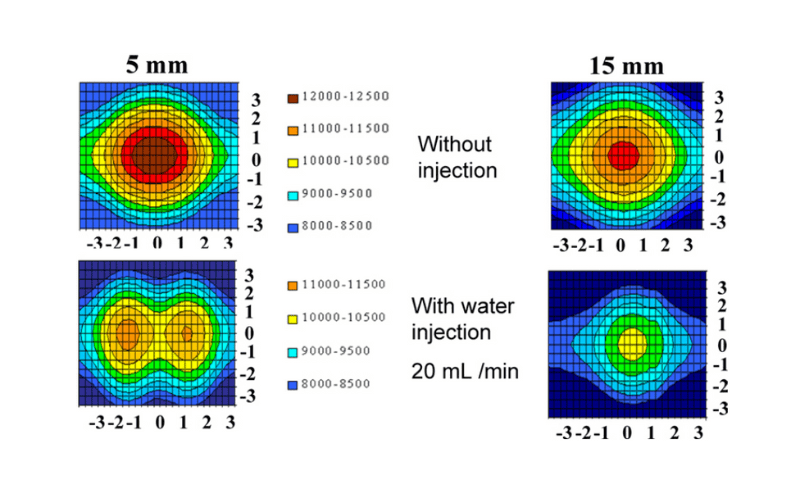

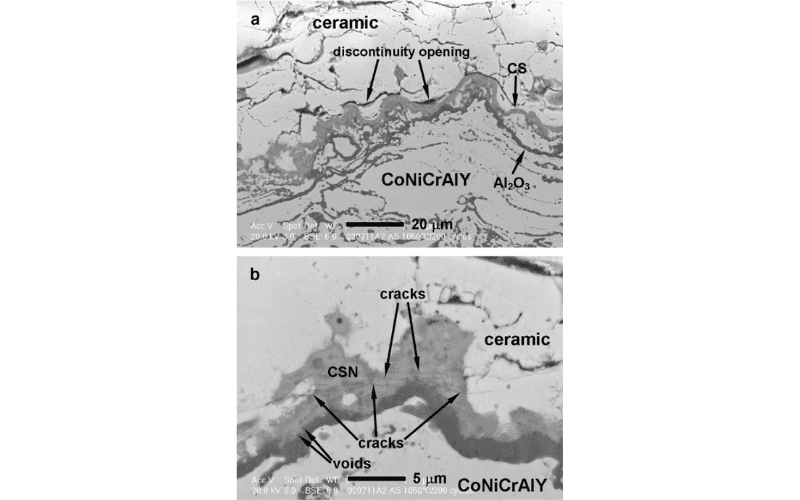

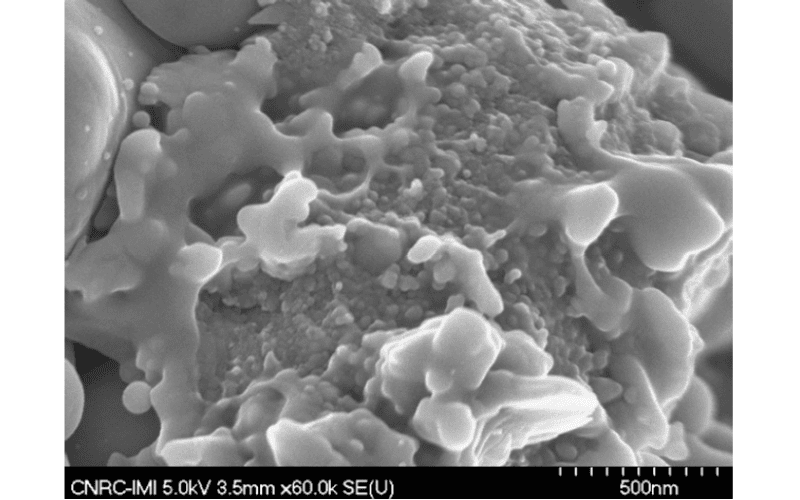

Chromium carbide-based thermally sprayed coatings are widely used for high temperature wear applications (typical temperature range from 540 to 900 […]

Engineering HVOF-Sprayed Cr3C2-NiCr Coatings: The Effect of Particle Morphology and Spraying Parameters on the Microstructure, Properties, and High Temperature Wear Performance