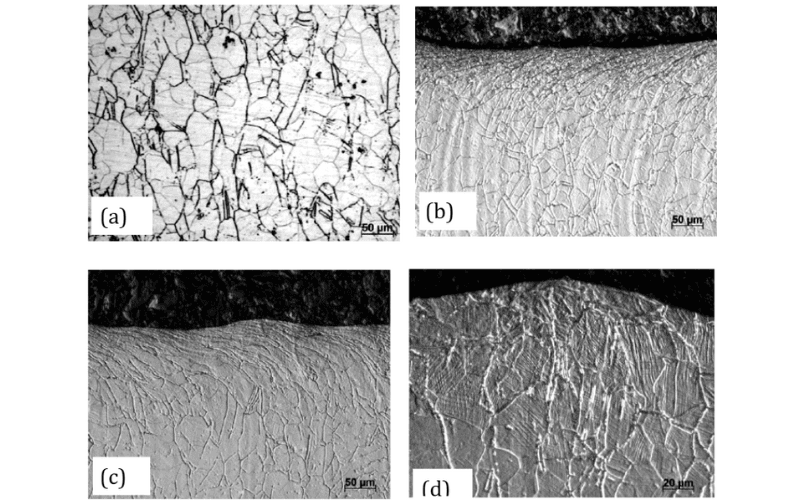

Since the early of 2000s, there has been significant interest in surface nanocrystallisation using the so-called surface mechanical attrition treatment […]

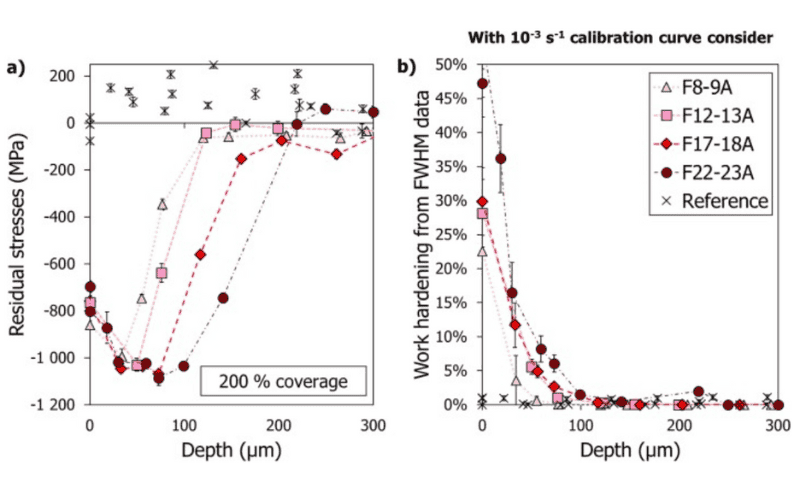

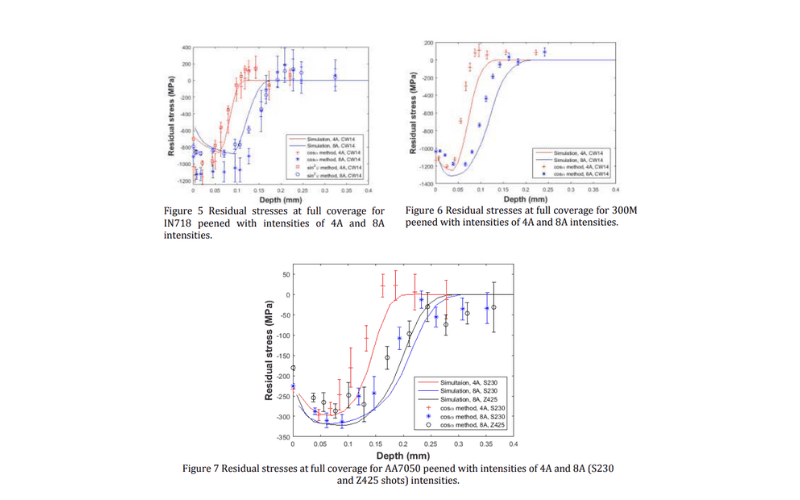

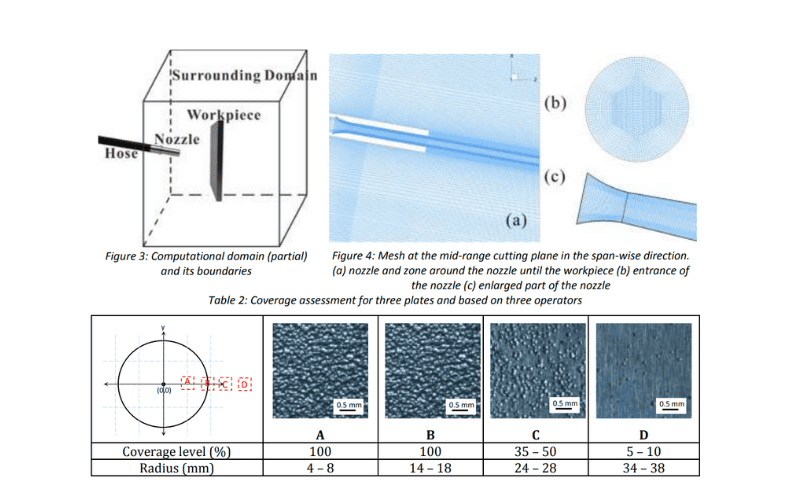

Nanocrystallisation On The Surface Of Superalloy In718 Component With A Commercial Shot Peening Process