December 19, 2022

Deposition, Microstructure and Thermal Cycling Performance of Strain-Tolerant Thermal Barrier Coatings

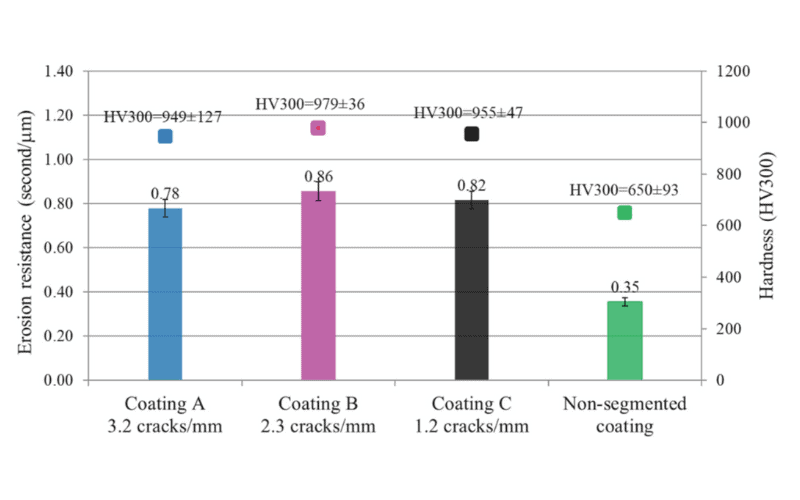

Thermal barrier coatings (TBCs) with high thermal strain tolerance and erosion resistance are strongly desired in gas turbine engines. Air plasma-sprayed (APS) strain-tolerant dense vertically cracked (DVC) TBCs are now one of the standards used for components of gas turbines. The APS DVC TBCs microstructure is typically achieved utilizing high enthalpy plasma conditions at short standoff distance (* 60 mm) in order to achieve larger tensile stress for vertical crack formation. However, shorter standoff distances bring new challenges and are not practical when coating the large and complex geometries of blades and vanes since the plasma torch may collide with the component during spraying. Therefore, there is a need to develop DVC TBCs at longer standoff distances. In this work, dense and strain-tolerant yttria stabilized zirconia thermal barrier coatings exhibiting various vertical crack densities were developed using the high enthalpy TriplexPro plasma torch at spray distances C 100 mm. The relationships among spray distances, particle in-flight states, deposition temperatures and coating microstructures were investigated. With the increase in spray distance, both the particle temperatures and vertical crack densities decrease. Coatings with vertical crack densities * 3.2 cracks/mm and * 1.2 cracks/mm were successfully made at standoff distances 100 mm and 150 mm, respectively. The effect of vertical crack densities on coating durability was evaluated in furnace cycling testing (FCT) and burner rig thermal shock testing. Coatings with higher vertical crack densities showed longer thermal cycling lives in both the FCT and burner rig test.

Keywords: burner rig test, dense vertically cracked (DVC), furnace cycle test, thermal barrier coatings, triplexPro-210

Originally published at Journal of Thermal Spray Technology (2023) 32:1108–1114

By Dianying Chen, Christopher Dambra, Mitchell Dorfman