February 2, 2026

Development And Experimental Validation Of A High-Power Conical RF-ICP Torch For Advanced Material Processing

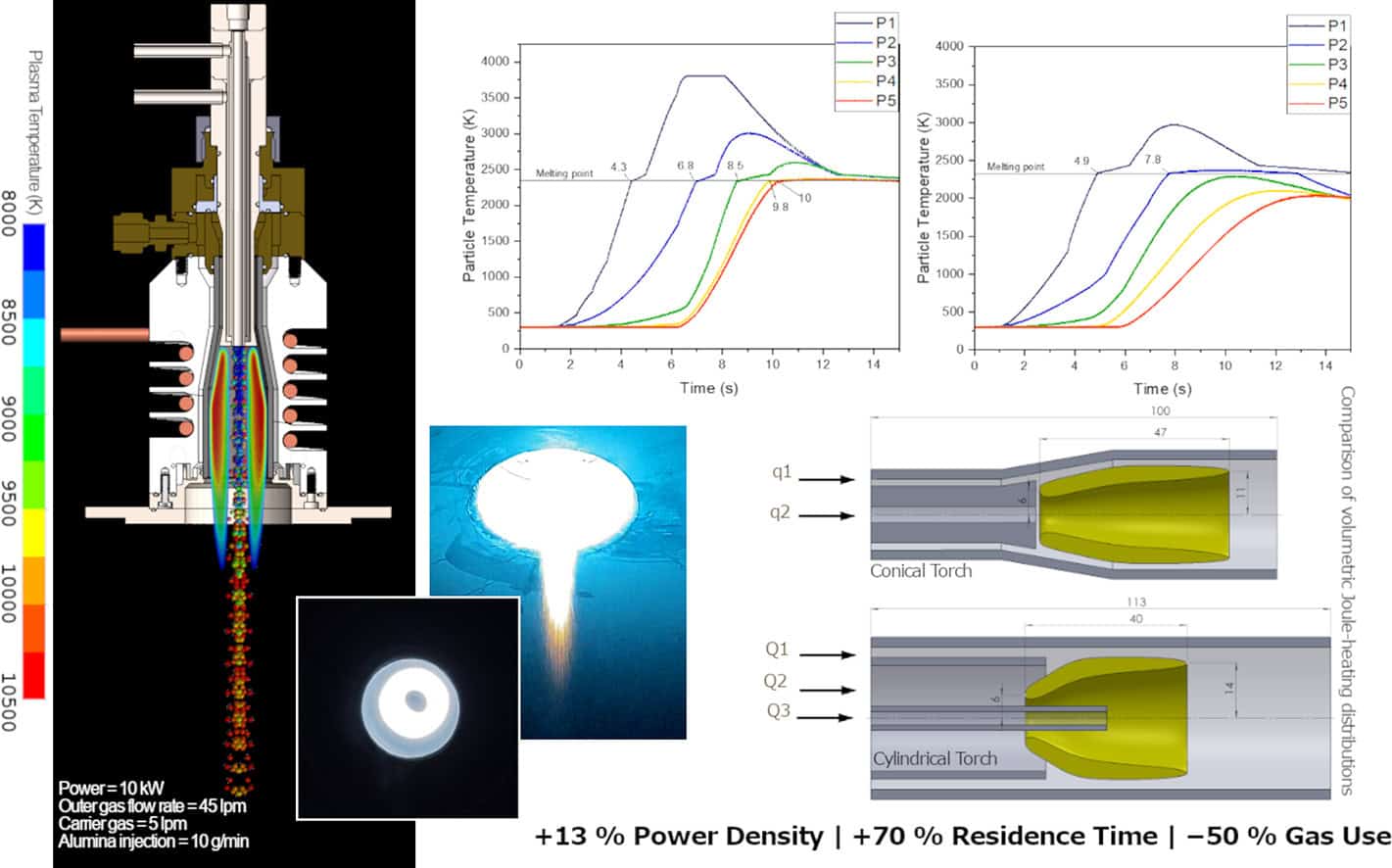

Radio-frequency inductively coupled plasma (RF-ICP) torches are widely used for high-temperature powder processing; however, conventional cylindrical designs distribute RF energy over a broad volume, resulting in low power density, high argon consumption, and non-uniform particle heating. This study presents the design, fabrication, and experimental validation of a high-power conical RF-ICP torch developed to address these limitations. A two-dimensional axisymmetric magneto-hydrodynamic model was implemented in ANSYS Fluent to optimize torch geometry and operating parameters. Model predictions were validated on a 13.56 MHz, 20 kW experimental platform using DPV-2000 particle diagnostics and cooling-water energy-balance measurements.

Compared with a benchmark cylindrical torch, the conical configuration achieved a 13% higher volumetric power density and extended the axial high-temperature zone by 27%, indicating enhanced plasma confinement. At 10 kW and an outer-gas flow rate of 50 L·min−1, measured particle temperatures and velocities (2300–3000 K; 29–65 m·s−1) showed good agreement with simulations. The conical torch generated an axial jet velocity of approximately 77 m·s−1 and increased particle residence time by about 70%, enabling efficient spheroidization. The torch demonstrated 25–50% lower gas consumption confirming the suitability of the conical RF-ICP torch for industrial-scale material processing applications.

Originally published at Applied Thermal Engineering (Volume 289, Part 2, March 2026)

By Ali Ebrahimi, Sina Alavi, and Javad Mostaghimi