April 29, 2024

Development and Understanding of CMAS Coating on YSZ Using APS Technique

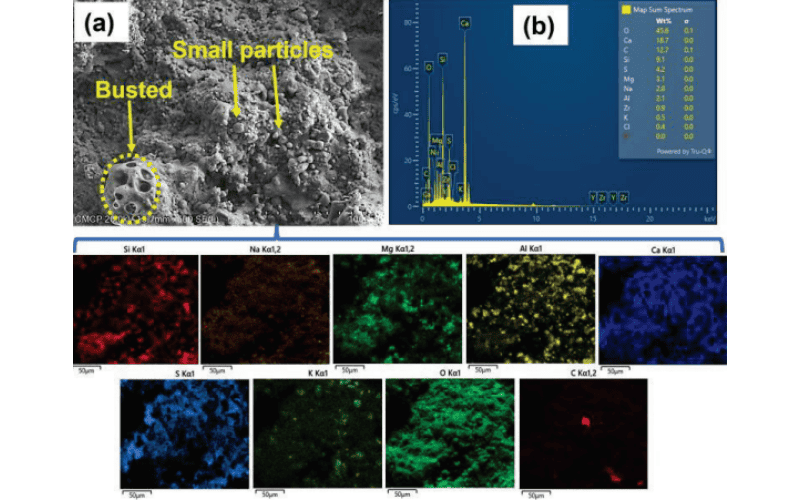

The ingestion of siliceous particulate debris into the gas turbine engines during operation caused the deposition of so-called CMAS (calcium-magnesium-alumino-silicate) on the hotter thermal barrier coating (TBC) surfaces. The penetration of these particles into the TBC at temperatures above 1200°C caused the loss of strain tolerance and premature failure of the TBCs. To mimic real-world conditions, a commercially available CMAS precursor dust powder was sprayed onto 8YSZ coatings using an atmospheric plasma spraying process. The substrate temperature was maintained at an average of 1100°C and 525°C during spraying. The effect of the spraying parameters on the deposition, microstructure, and composition of the CMAS coatings was investigated. In addition, to understand the CMAS build-up on the high-temperature surfaces, the CMAS splat formation behavior was also analyzed on the polished samples at temperatures ~1100°C. SEM/EDS analyzes were performed to identify and quantify the elements of the CMAS deposits. It was found that the surface temperature, deposition time, and different nozzles could play a significant role in having different phases of CMAS deposits.

Key words: atmospheric plasma spraying, calcium-magnesium-alumino-silica coatings, chemical composition, microstructure, thermal barrier coatings, yttria-stabilized zirconia

Originally published at ITSC2024 Proceedings online paper (Paper No: itsc2024p0176, pp. 176-184; 9 pages)

By Amit Roy, Fadhel Ben Ettouil, Rogerio S. Lima, Christian Moreau