September 11, 2025

Effect of Gun Geometry on MCrAlX Coating Microstructure and In-Flight Oxidation Deposited by Low-Temperature High-Velocity Air Fuel

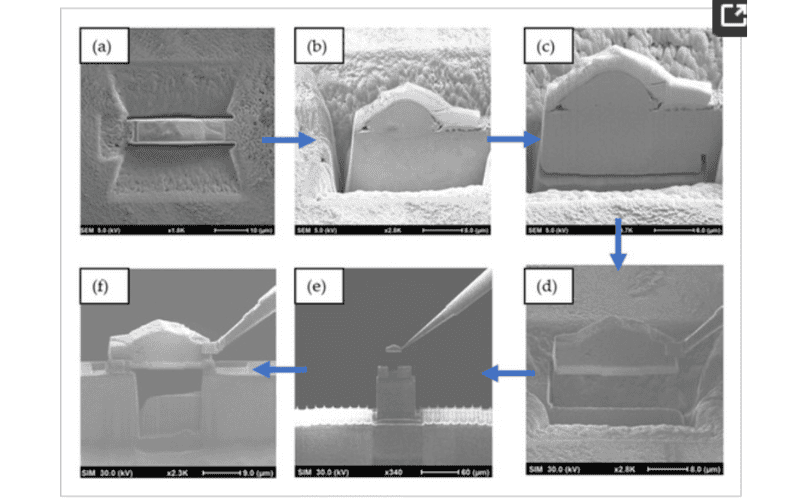

Aircraft gas turbine blades operate in aggressive, generally oxidizing, atmospheres. A solution to mitigate the degradation and improve the performance of such components is the deposition of thermal barrier coatings systems (TBCs). High-velocity air fuel (HVAF) is a very efficient process for coating deposition in TBC systems, particularly for bond coats in aerospace applications. However, its low-temperature variant has received little attention in the literature and could be a promising alternative to limit oxidation during spraying when compared to conventional methods. This study has the main objective of analyzing how the geometry of the low-temperature HVAF gun influences the microstructure and the in-flight oxidation of MCrAlX coatings. To that end, a low-temperature HVAF torch is used to deposit MCrAlX coatings on a steel substrate with different nozzle lengths. In-flight particle diagnosis is used to measure the MCrAlX particle velocity, and to correlate to the nozzle geometry and to analyze its influence on the final coating. The microstructure of the coatings is assessed by scanning electron microscopy (SEM) and the material oxidation is analyzed and measured on a field emission scanning transmission electron microscope (FE-STEM) equipped with focused ion beam (FIB) and by Energy Dispersive Spectroscopy (EDS).

Key words: high-velocity air fuel; HVAF; bond coat; TBC; NiCoCrAlY; aluminum; oxidation

Originally published at Coatings (2025, 15(3), 357)

By Murilo Sergio Lamana,Aravind Kumar Thoutam, Bruno C. N. M. de Castilho, Fadhel Ben Ettouil, Ritvij Chandrakar, Stephanie Bessette, Nicolas Brodusch, Raynald Gauvin, Ali Dolatabadi and Christian Moreau