January 25, 2021

Effect of Powder Particle Size and Spray Parameters on the Ni/Al Reaction During Plasma Spraying of Ni-Al Composite Powders

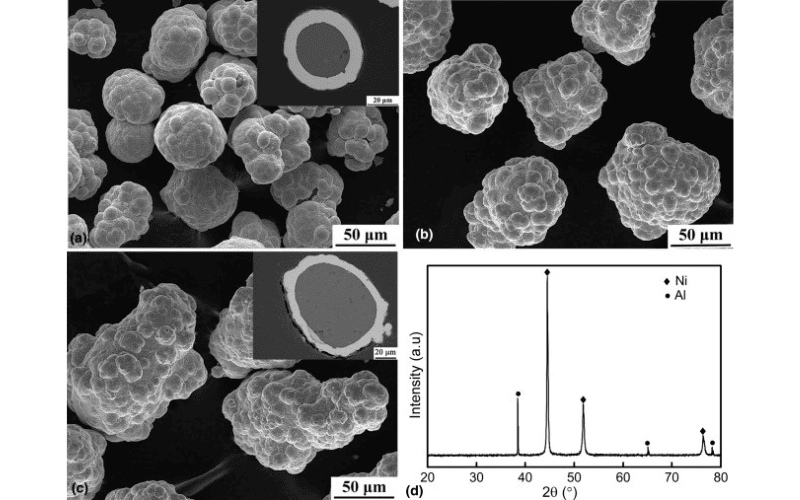

It was known for long that Ni-Al composite powders can be used to deposit self-bonding coating as a bond coat for common ceramic coatings due to the exothermic reaction between Ni and Al. However, it was found that with commercial Ni-Al composite powders with a large particle size, it is difficult to ignite the self-propagating reaction between Ni and Al to form Ni-Al intermetallics by plasma spraying. In this study, Ni-Al composite powder particles of different sizes were used to prepare Ni-Al intermetallics-based coatings by plasma spraying. The dependencies of the exothermic reaction between Ni and Al and the coating microstructure on powder particle size and spray parameters were investigated. The phase composition, microstructure, porosity and oxide content of the coatings were characterized by x-ray diffraction, scanning electron microscope and image analyzing. The results show that particle size of Ni-Al composite powders is the dominant factor controlling the exothermic reaction for the formation of Ni-Al intermetallics during plasma spraying. When the powders larger than about 50 μm are used, the reaction forming aluminide cannot complete even by heating of plasma flame generated at high plasma arc power. However, when smaller powders less than 50 μm are used, the exothermic reaction can completely occur rapidly in plasma spraying, contributing to heating of Ni-Al droplets to the highest temperature for development of the self-bonding effect. The positive relationship between molten droplet temperature and tensile adhesive strength of the resultant coatings is recognized to confirm the contribution of high droplet temperature to the adhesive or cohesive strength.

Keywords: Ni-clad Al, powder particle size, exothermic reaction, Ni-Al intermetallics, plasma spraying, self-bonding

Originally published at J Therm Spray Tech. (2021; 30(1-2): 181–195)

By Li Zhang, Xian-Jin Liao, Shan-Lin Zhang, Xiao-Tao Luo, and Chang-Jiu Li