October 22, 2025

Formation Dynamics Of Composite Ni-Graphite Abradable Coatings

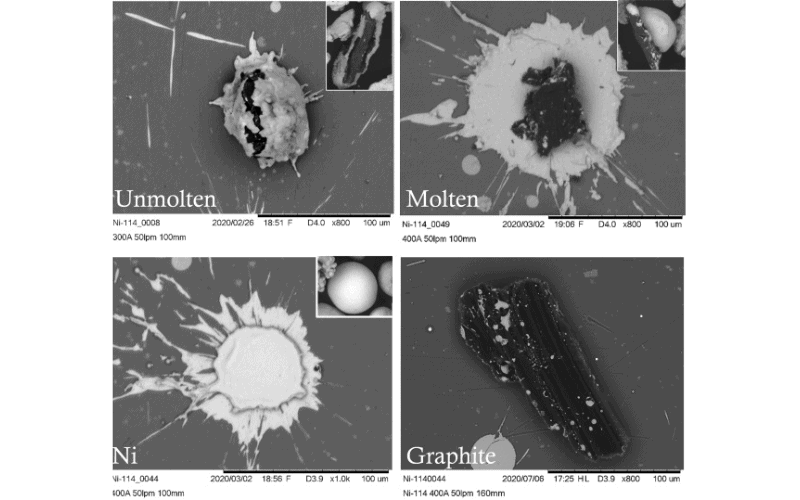

In this study, a fundamental understanding of the formation dynamics of Ni-graphite porous/friable overlay thermal spray coatings is investigated for clearance control in turbo-machinery. The concept relies on the coating providing abradability to yield tight tolerances, enabled by the unique microstructure. Although widely used, optimizing the microstructure of such dissimilar composite can be challenging. Particle transformation in flight is investigated through particle diagnostics and scanning electron microscopy analysis of the sprayed materials. Thermal and kinetic energy of particles were modified by changing current, argon flow and spray distance. Splats were categorized and quantified for each of the processing conditions, providing a more complete understanding of the coating composition. The coatings’ mechanical response was assessed as a function on the elastic modulus and stresses, measured by the curvature method, and by superficial Rockwell hardness 15Y. Results show that Ni-cladded graphite particles undergo an important shape transformation characterized by the separation of Ni and graphite phases, which is strongly dependent on the processing parameters. In addition, the feedstock also undergoes various physicochemical transformations, including carbon solubilization in Ni, nickel carbide (Ni₃C) formation, graphite oxidation, graphite sublimation, nickel oxidation (NiO), nickel vaporization and surface graphitization of Ni-cladded graphite particles. This research shed light to better understand how Ni-graphite coatings are built and affected by processing parameters, contributing towards the engineering of more predictable Ni-Graphite abradable coatings.

Originally published at Surface and Coatings Technology (Volume 516, 15 November 2025, 132755)

By Juliane Ribeiro da Cruz, Sanjay Sampath