March 20, 2002

High Weibull Modulus HVOF Titania Coatings

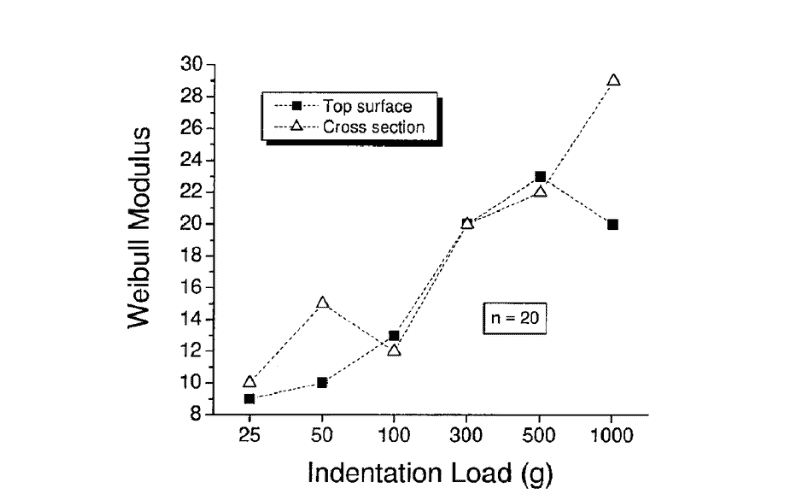

The mechanical behavior of high-velocity oxyfuel (HVOF) sprayed titania (TiO2) coatings was evaluated using Vickers hardness measurements on the cross section and top surface. The distribution of hardness values for the cross-section and top surface under 25, 50, 100, 300, 500, and 1000 g loads was analyzed via Weibull statistics. The coating microstructure was evaluated using scanning electron microscopy (SEM). It was observed that the microstructural features were similar in the top surface and cross-section, different from the lamellar structure commonly found in thermal spray coatings. X-ray diffraction (XRD) analysis identified rutile as the major coating phase. The in-flight sprayed particle parameters such as temperature and velocity were determined using a commercial diagnostic system based on pyrometry and time-of-flight measurements. The uniformity of the microstructure resulted in a near isotropic behavior of the mechanical properties, such as hardness, in the coating cross-section and top surface. High Weibull modulus values were observed when compared with results of other thermal spray coatings available in the literature. These initial results should contribute to a more general understanding of the conditions necessary to achieve coatings with high uniformity and assist in the engineering of coating microstructures for specific applications.

Key words: hardness, high-velocity oxyfuel, titania, tailoring of microstructures, Weibull modulus

Originally published at Journal of Thermal Spray Technology (Volume 12, pages 240–249, 2003)

By R. S. Lima, B. R. Marple