May 10, 2024

Influence of Deposition Parameters on the Formation of Surface Cracks in Segmented Aps-Tbcs

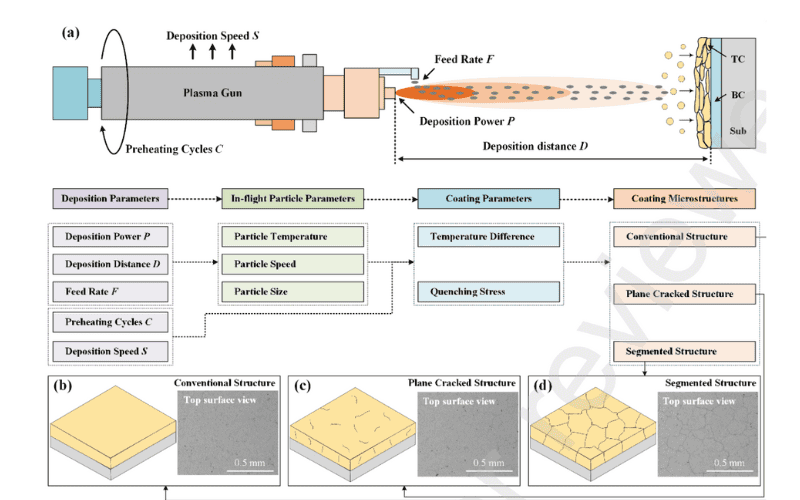

Thermal barrier coating system (TBCs) prepared using the Air plasma spray (APS) method are widely recognized as the most prevalent thermal insulation materials in both land-based engines and aerospace engines. The surface cracks, which are generated due to significant thermal stress during deposition, is widely acknowledged as an effective strategy for enhancing the strain tolerance and durability of APS-TBCs. Consequently, the segmented structure featuring channeled surface cracks has been identified as a highly exceptional type of APS-TBCs with remarkable strain tolerance and long-term serviceability. However, the underlying mechanisms governing the relationship between deposition parameters and segmental cracking responsible for surface crack formation in APS-TBCs remain incompletely elucidated. In this article, we conducted experimental analysis to investigate the sensitivity of five chosen deposition parameters on the induced peak quenching stress in top coat (TC) during fabrication. Subsequently, we established a quantitative relationship between the five deposition parameters and the peak quenching stress, enhancing our understanding of how these parameters influence segmental cracking. During our investigation, we monitored in-flight particle parameters using the DVP-2000 equipment and coating mechanical parameters using a self-developed real-time curvature measurement equipment under different deposition conditions. This allowed us to further analyze the correlations between particle and coating parameters. Based on their relative impact on peak quenching stress, we determined that the sensitivity of these five deposition parameters on segmental cracking is as follows: deposition power > deposition speed > preheating cycles > deposition distance > feed rate. Furthermore, based on experimental results, we recommend setting optimum deposition parameters as follows: highest power, lowest speed, highest preheating cycles, lowest distance, and lowest feed rate to improve the possibility of fabricating segmented APS-TBCs with controllable density of surface cracks. These experimental observations provide valuable guidance for modifying APS equipment or optimizing its parameters to achieve straightforward and efficient fabrication of segmented APS-TBCs.

Key words: Air plasma sprayed, Thermal Barrier Coatings, Segmented structure, Surface cracks, Deposition parameters.

By Yang, LiuYu and Chen, Yiwen and Li, Dingjun and Jiang, Peng