April 15, 2001

Influence of Plasma Spray Parameters on In-Flight Characteristics of ZrO2–8 wt% Y2O3 Ceramic Particles

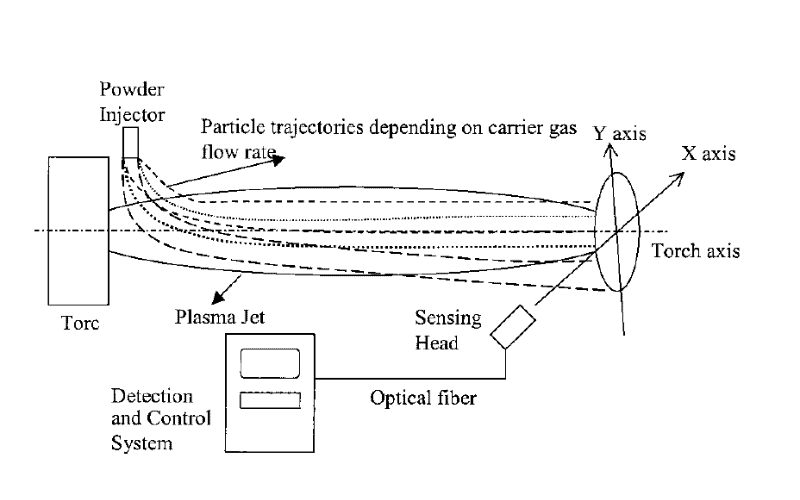

Yttria-partially-stabilized zirconia was atmospherically plasma sprayed by systematically varying the process conditions including carrier gas flow rate, torch power, standoff distance, and Ar/H2 ratio in the plasma gas mixture. The in-flight particle parameters such as temperature, velocity, number, and size were determined using a commercially available diagnostic system. The particle parameters were controlled by the particle trajectory in the plume and plasma jet characteristics. The average temperature and the velocity of particles, which reached their maximum at an intermediate carrier gas flow rate of 3.5 L/min, varied as much as 6% and 25%, respectively, with a 75% variation in the carrier gas flow rate by going from the lowest to the intermediate rates. The average temperature and the velocity of particles were lower for a lower torch power, a higher Ar/H2 ratio, and a larger standoff distance. It was necessary to obtain data on particle populations larger than 1000 for statistically reliable and reproducible information from the diagnostic system.

Originally published at Journal of the American Ceramic Society(April 2001)

By Ahmet Kucuk, Rogerio S. Lima, Christopher C. Berndt