February 9, 2026

Reducing Heat Treatment Time And Temperature For Dense Crystalline Ytterbium Disilicate Environmental Barrier Coatings

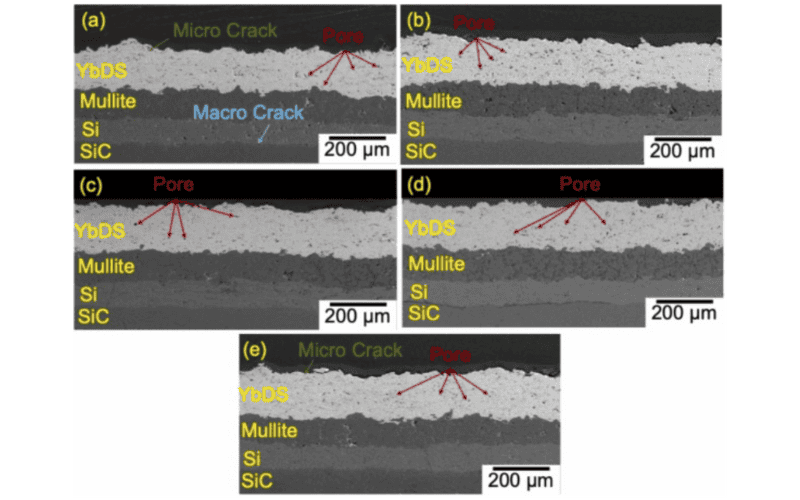

Ytterbium disilicate (YbDS) environmental barrier coatings (EBCs) are deposited by atmospheric plasma spray (APS) to protect aeroengine components made of SiCfiber(f)/SiC ceramic matrix composites. During deposition, rapid solidification of molten YbDS particles upon impact creates an amorphous structure which needs to be crystallized. This study optimized crystallization heat treatment for dense (∼2 % porosity) EBCs with as-sprayed crystallinity between 10 % and 50 %. Stable ytterbium silicate phases (YbDS and Yb₂SiO₅ (YbMS)) are formed above 1200 °C, regardless of initial crystallinity. EBCs with crystallinity of 15 % produced metastable phases at 1100 °C, requiring at least 10 h to transform them into stable phases, while coatings with 50 % crystallinity formed stable phase after only 4 h. The morphology and hardness of EBCs after crystallization are shown to be comparable irrespective of the heat treatment temperature. This demonstrates that partially crystalline as-sprayed YbDS can be crystallized faster and at lower temperatures, potentially reducing production costs.

Key words: Environmental Barrier Coatings; Ytterbium Monosilicate; Ytterbium Disilicate; Crystallization; Phase Analysis; Atmospheric plasma spray; Thermal annealing

Originally published at Journal of the European Ceramic Society (Volume 46, Issue 8, July 2026, 118190)

By P. Khamsepour,,P. Bansal, D. Guay, A.C. Tavares, B. Guerreiro, R.S. Lima, K.R. Beyerlein