Shotmeter 4.0

The production-friendly shot peening sensor

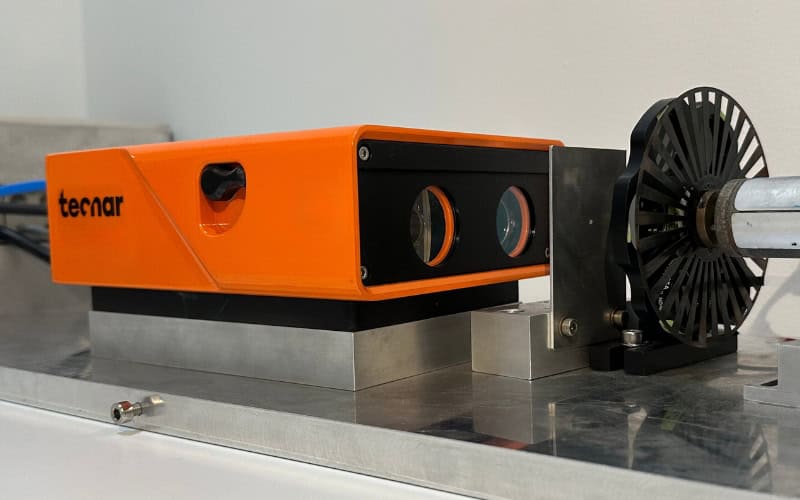

The Shotmeter 4.0 is an easy-to-use shot peening sensor for measuring in-flight shot media velocity. It ensures peening consistency, quality control, faster process development, and set-up transfer.

Talk to an expertShot peening process control

Control your velocity to control your intensity

Make shot peening diagnostics accessible and time-efficient with the Shotmeter 4.0. This reliable, affordable sensor is designed for all shot peening shops to achieve repeatable peening intensity.

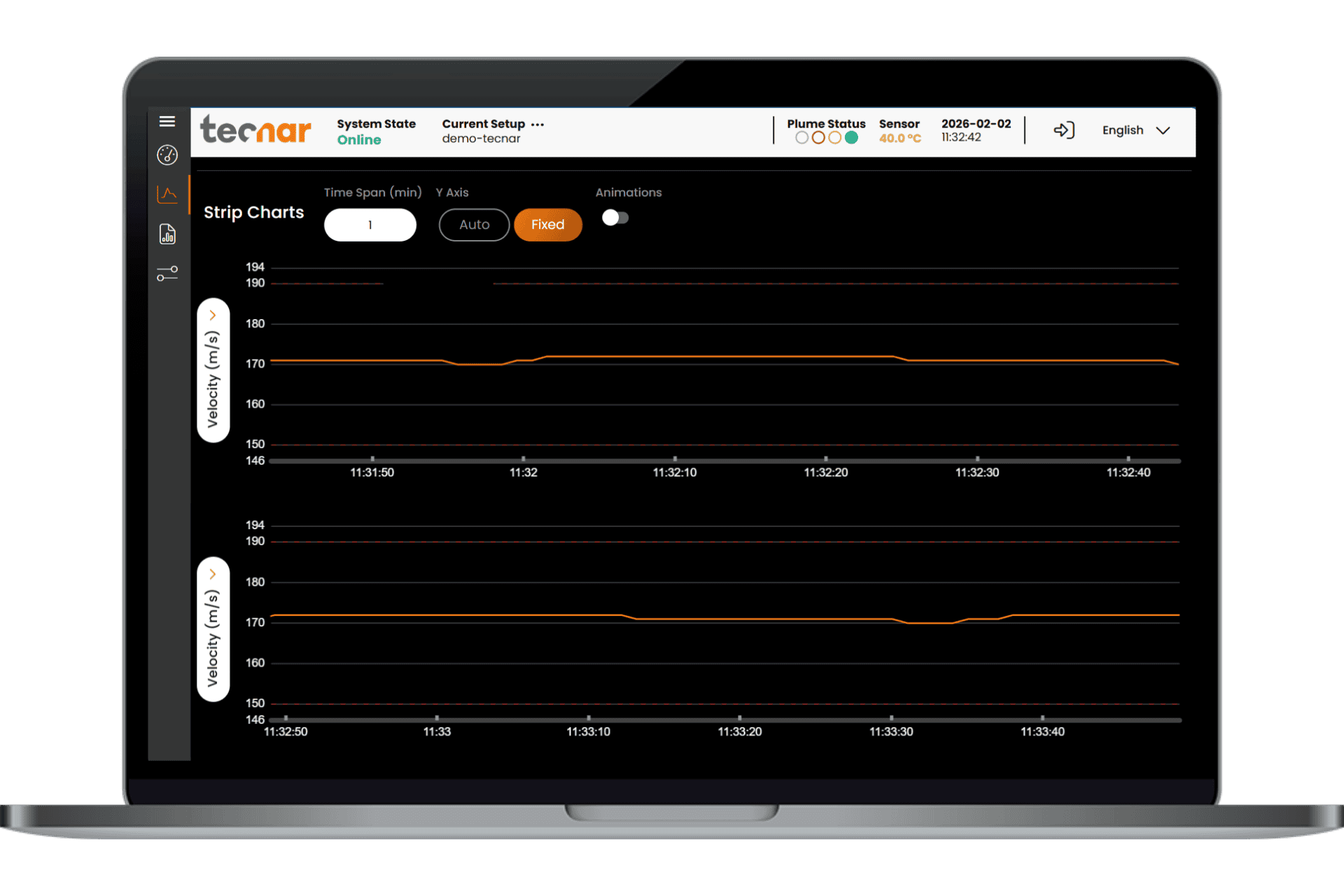

Shot velocity

Relative feed rate

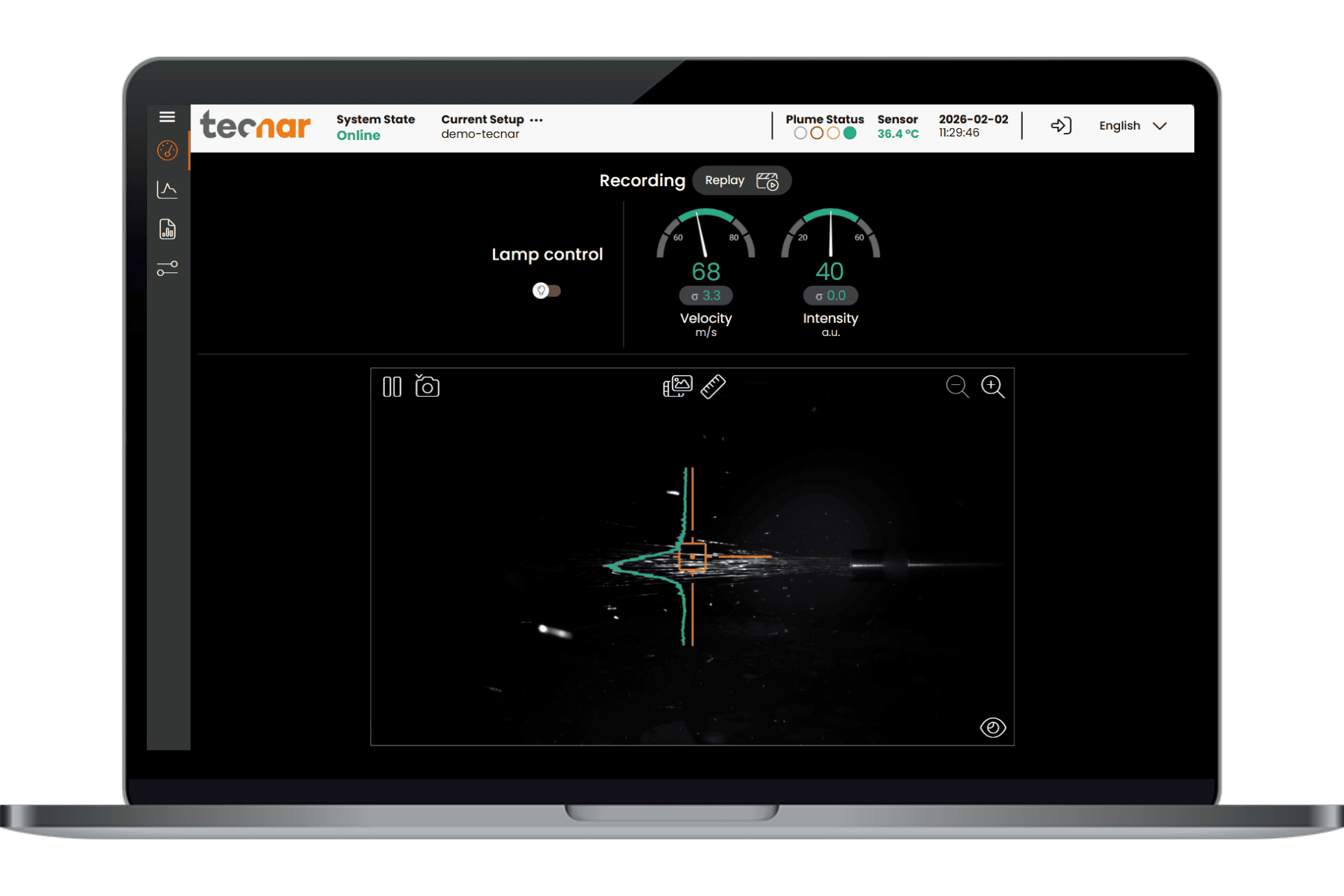

Shot stream visualization

The Shotmeter 4.0 advantage

AMS2432E compliant

SAE International’s October 2022 latest revision E of AMS2432 confirms media velocity sensors as an approved alternative to Almen strips for production part shot peening.

Easily achieve targeted intensity

Shot peening processes are sensitive to intensity, which is directly correlated with media velocity. Achieving repeatable velocity is the key to maximizing consistency. Monitoring real-time in-flight velocity can help production managers monitor and attain faster:

- Process replication

- Equipment calibration

- New process development and validation

Reduce cost per part

- Quicker peening parameter development and process optimization

- Easy cell-to-cell parameter transfer and replication

- Quicker equipment qualification for new hardware

- Direct correlation between velocity and Almen strip deflection

NIST and Nadcap audits

Digital data collection and traceability for successful Nadcap® audits. Velocity measurements are factory-calibrated using a NIST-traceable calibration bench to recreate actual conditions in the field.

Key features

Go/No Go tool

Automatically trigger go/no go decisions based on data.

New camera

The Shotmeter 4.0 includes a camera responsible for media stream geometry analysis.

Stability analysis

Along with the average readings, it measures the stability of the stream characteristics.

Ease of integration

Ranging from the default I/Os on the controller to complete control via HTTP commands or OPC UA, it offers flexible options for seamlessly integrating the sensor.

Alignment assist

Easy alignment of the nozzle through the camera.

Set-up files

Saves and recalls software parameters based on conditions.

Production reports

Generates production reports with a single click in the user interface or with a single signal via our integration options.

Self install

Complete documentation allowing for self-install and initial testing with the machine.

Remote training included

A remote training session with one of our Shotmeter specialists is included with the purchase.

Technical specifications - Shotmeter 4.0

Measurements

Particle velocity range

10 m/s to 1500 m/s at 2% precision

33 f/s to 4900 f/s at 2% precision

Measurement volume information

Velocity measurement area

⌀2.2 mm = 3.8 mm²

⌀0.087 in. = 0.0059 in.²

Working distance

125 mm

4.92 in.

Plant supplies

Power requirements

100-120 or 200-230 VAC, 50-60 Hz Auto-switch

Air supply

Supply clean & dry cooling air at 1.7–2.7 bar to the sensor head

Supply clean & dry cooling air at 25–40 psi to the sensor head

Dimensions

Sensor head

196 mm x 83 mm x 212 mm - 3.3 kg

7.7 in. x 3.3 in. x 8.3 in. - 7.3 lbs

Controller

230 mm x 132 mm x 240 mm - 6.6 kg

9.1 in. x 5.2 in. x 9.4 in. - 14.6 lbs

Shipping specifications

Total dimentions

660 mm x 432 mm x 330 mm

26 in. x 17 in. x 13 in.

Total weight

13.2 kg

29 lbs

Sensor head dimensions

279 mm x 229 mm x 330 mm

11 in. x 9 in. x 13 in.

Sensor head weight

4.1 kg

9 lbs

Interested in the Tecnar Shotmeter 4.0?

Leave your details so our experts can contact you.

Our team will answer all your questions and suggest the best solution for your needs.