September 19, 2025

Single-Particle Impact of Ti6Al4V and Ti-5553 in Cold Spray: A Novel Approach to Flattening Ratio and Selecting Johnson–Cook Model Parameters

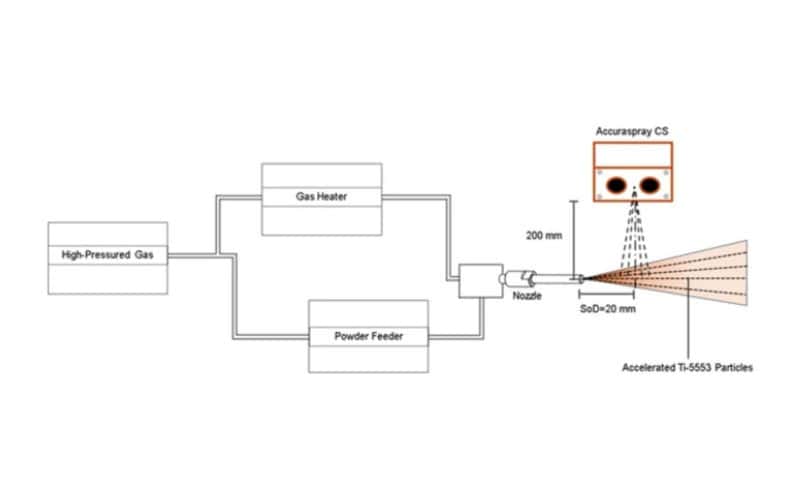

The application of Finite Element Analysis (FEA) in cold spray (CS) provides valuable information about material deformation and stress distribution. The Johnson–Cook (JC) model is widely used to simulate material behavior, while the particle Flattening Ratio (FR) is commonly used to assess the deformation pattern and mechanism. FR has also been employed to evaluate and select appropriate JC model parameters. Experimental FR values can be obtained from a cross-sectional view of splats; however, the accuracy of these values can be affected by the sectioning location. This study introduces a novel approach for experimental FR observation by integrating top and cross-sectional views of Ti6Al4V and Ti-5553 deposited particle splats, addressing the limitations of the conventional cross-sectional FR method. The influence of the sectioning region on FR values was systematically evaluated through numerical and experimental analyses. Experimental FR results show that off-axis sectioning leads to overestimating FR values, with increases of 25.98% for Ti6Al4V and 15.45% for Ti-5553. The differences in critical velocities obtained using the FEA between the two FR measurement approaches were approximately 24.61% for Ti6Al4V and 32.46% for Ti-5553. The findings highlight the importance of accuracy in FR measurement and its effect on JC parameter selection and FEA results.

Originally published in Journal of Thermal Spray Technology, September 17th 2025

By A. Ağır, C. J. Akisin, K. Singh, C. J. Bennett &, and T. Hussain