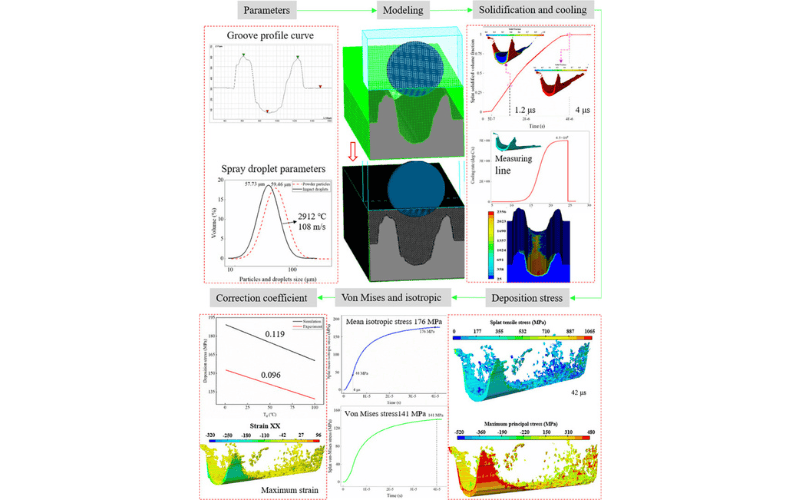

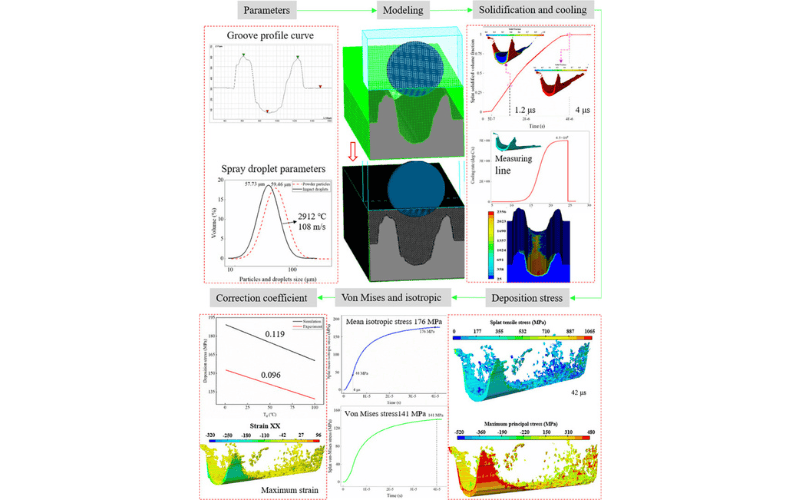

This study focuses on understanding the crucial phenomenon of deposition stress during the splat formation of plasma-sprayed droplets, which is […]

This study focuses on understanding the crucial phenomenon of deposition stress during the splat formation of plasma-sprayed droplets, which is […]

The first-of-its-kind use of the active learning (AL) framework in thermal spray is adapted to enhance the prediction accuracy of […]

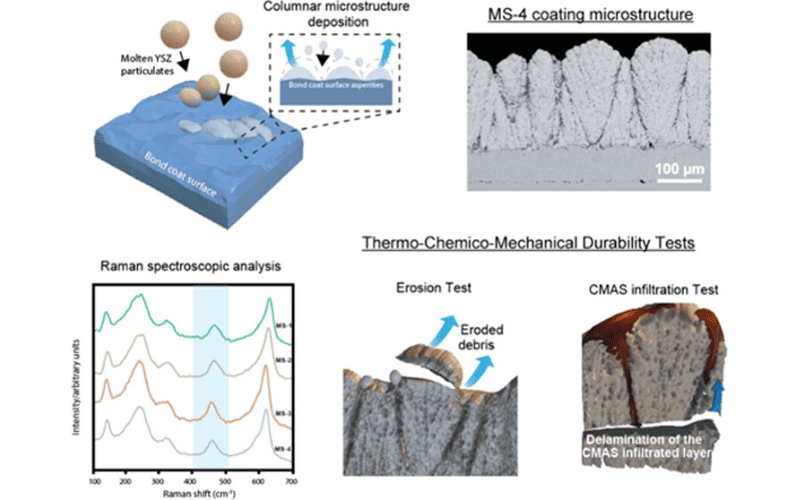

Contemporary gas turbine engines rely on thermal barrier coatings (TBCs), which protect the structural components of the engine against degradation […]

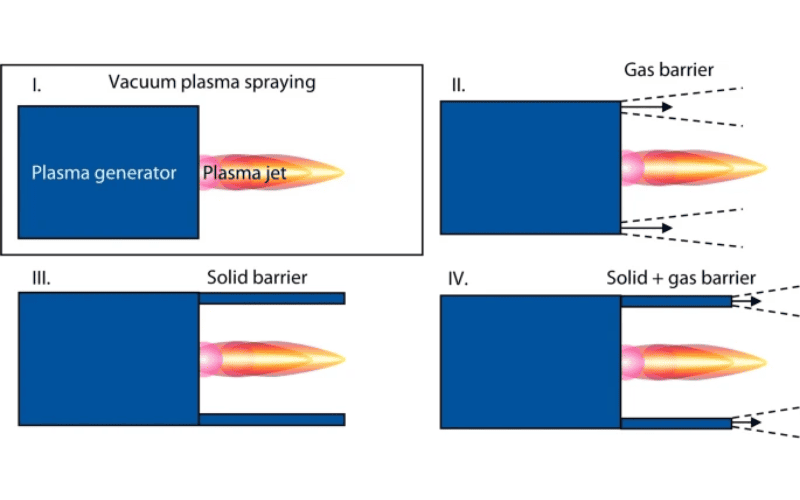

Plasma spraying is characterized by high flexibility, but has challenges of high energy consumption and oxidation of the metallic spray […]

The electrical and mechanical properties of cold-sprayed coatings dependon the particle size of the feedstock powder, as it greatly influences […]

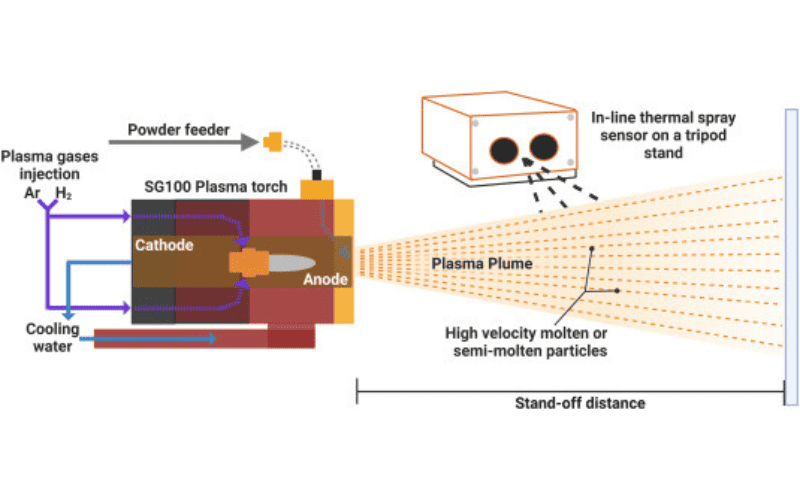

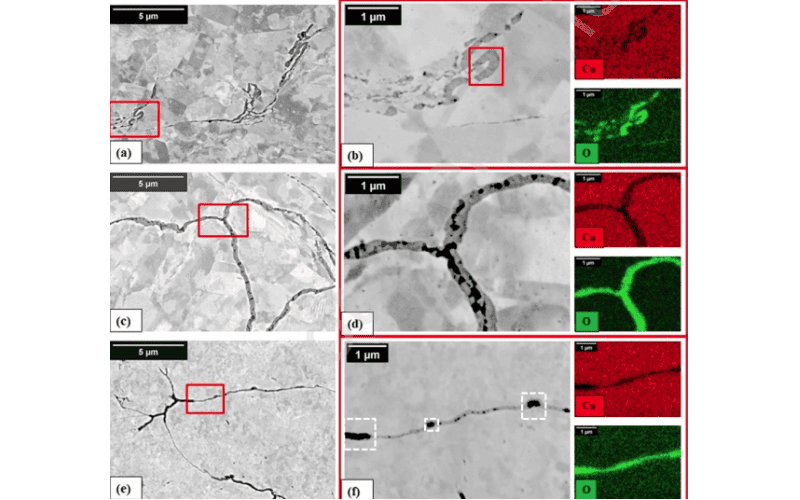

Thermal spray deposition (specifically Atmospheric Plasma Spraying, APS) is a well-established surface coating technology with a broad scope of applications […]

In this study, the plasma torch is utilized for the preparation of highly pure ZrO2 from zircon (ZrSiO4). The incorporation […]

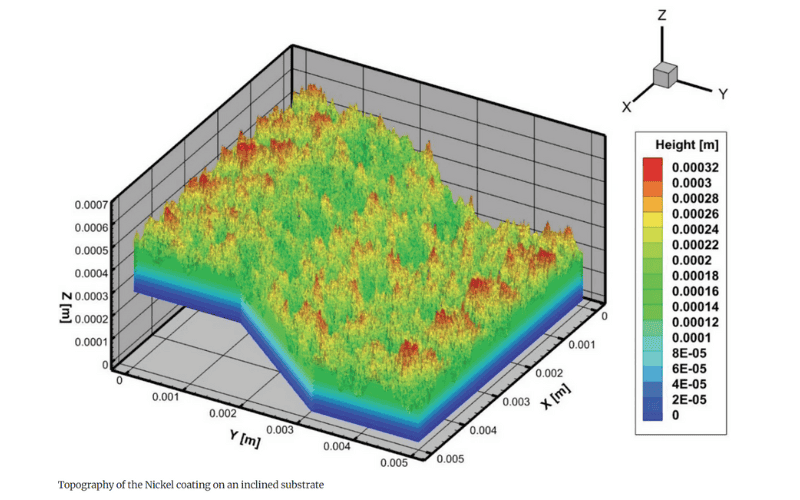

The main focus of this study is on simulation of coating formation on substrates with arbitrary shapes. For this purpose, […]

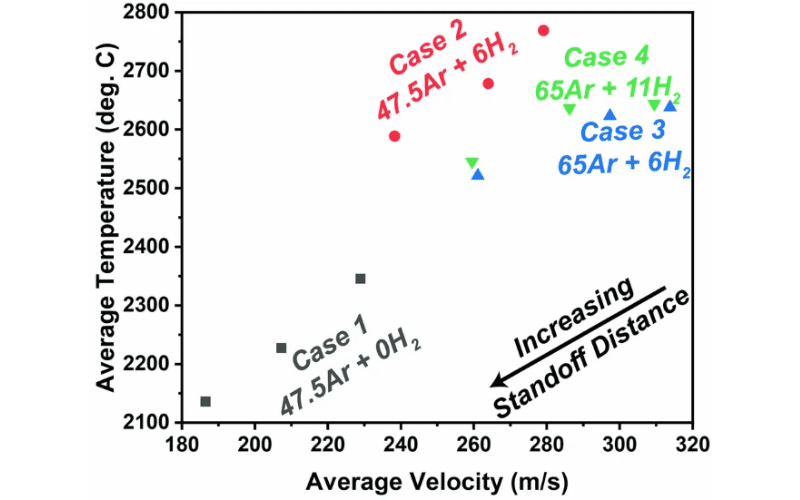

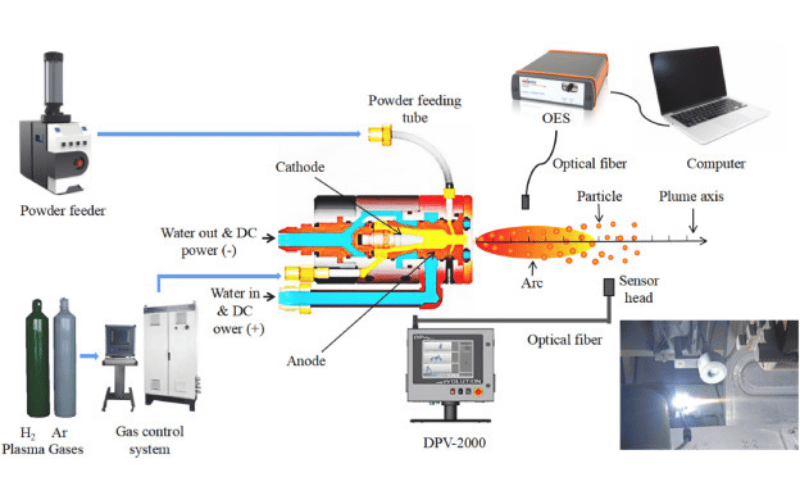

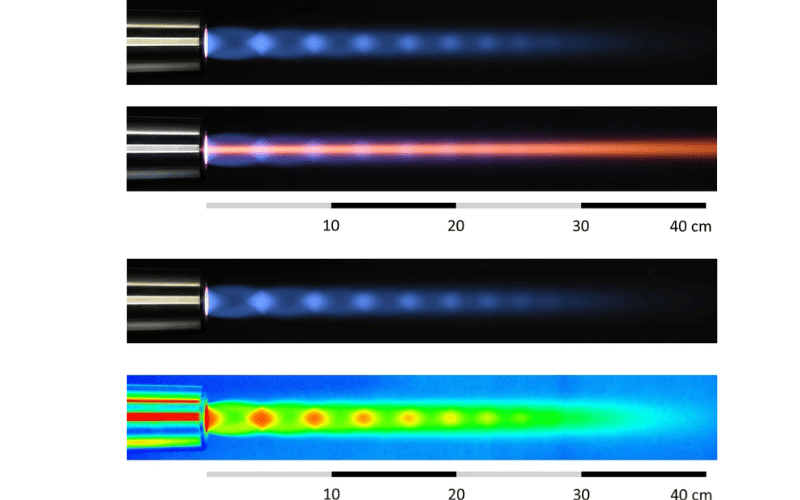

Driven by the search for an optimum combination of particle velocity and process temperature to achieve dense hard metal coatings […]