April 13, 2024

Processing–Microstructure–Properties of Columns in Thermal Barrier Coatings: A Study of Thermo-Chemico-Mechanical Durability

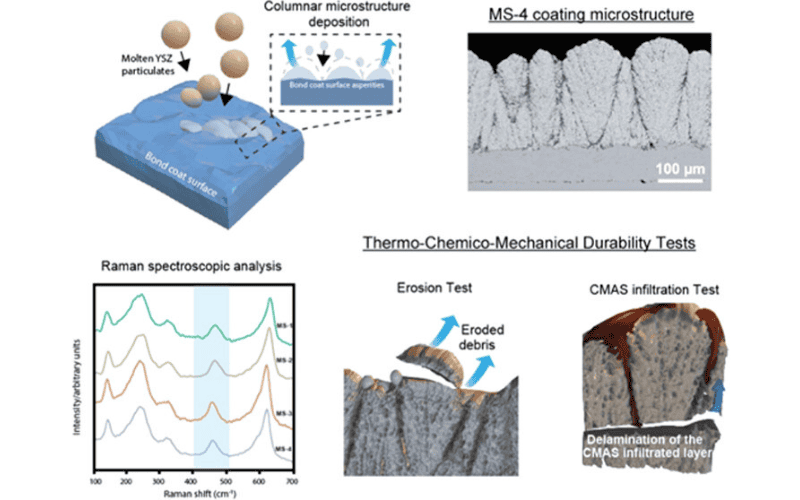

Contemporary gas turbine engines rely on thermal barrier coatings (TBCs), which protect the structural components of the engine against degradation at extremely high operating temperatures (1300–1500 °C). The operational efficiencies of aircraft engines have seen significant improvement in recent years, primarily through the increase in operating temperatures; however, the longevity of TBCs can be potentially impacted by several types of degradation mechanisms. In this comprehensive study, a wide range of novel columnar suspension plasma sprayed (SPS) coatings were developed for their erosion, calcium–magnesium–aluminum-silicate (CMAS), and furnace cycling test (FCT) performance. Through a comprehensive investigation, the first of its kind, we achieved a range of SPS microstructures by modifying the spray parameters and measuring their microhardness, fracture toughness, column densities, and residual stresses using Raman spectroscopy. We were able to produce dendritic, lateral, branched, and columnar microstructures with a unique set of processing parameters. Coatings enhanced with a refined columnar microstructure, achieved by modulating the distance from the plasma torch, exhibited superior thermal cycling resilience. Conversely, the development of a columnar microstructure with dendritic branches, obtained by decreasing the robot’s traversal speed during deposition, bolstered resistance to erosion and minimized damage from molten CMAS infiltration, thereby notably augmenting the coating’s lifespan and robustness. The pursuit of the optimal columnar microstructure led to the conclusion that for each SPS coating, a general framework of optimization needs to be conducted to achieve their desired thermo-chemico-mechanical resistance as the properties required for TBCs are intertwined.

Key words: thermal barrier coatings, suspension plasma spray, columnar microstructure, CMAS resistance, thermal cycling resistance, erosion resistance

Originally published at ACS Applied Materials & Interfaces (Vol 16/Issue 8, February 13, 2024)

By Siddharth Lokachari, Kah Leng, Acacio Rincon Romero, Nicholas Curry, Gyaneshwara Brewster, Andy Norton, Tanvir Hussain