October 22, 2025

A Study of Particle Heating and Oxidation Protection in a Modified Internally Injected Ar–H2 Atmospheric Plasma Spraying Torch

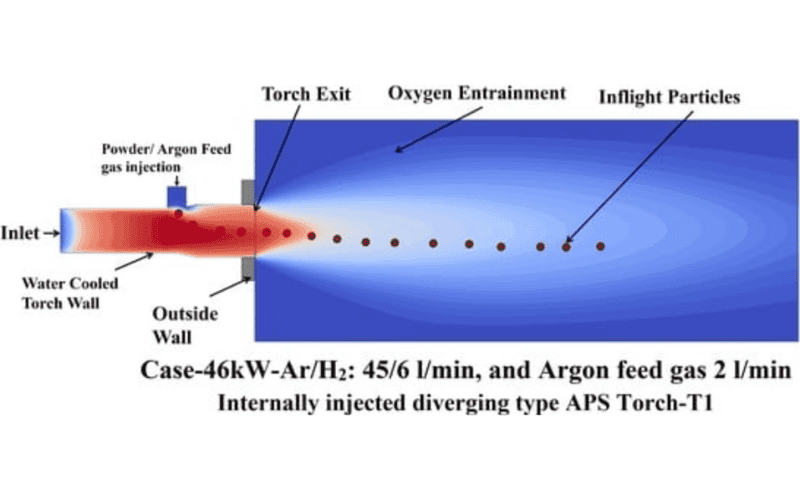

This study employs computational fluid dynamics (CFD) to analyze the in-flight dynamics of particles in an Ar–H2 atmospheric plasma spray (APS) torch with a modified diverging-type nozzle. The focus is on optimizing injection parameters—plasma gas flow rates, input power, and carrier gas flow rates—to enhance coating microstructure and deposition efficiency by achieving superheated molten metal droplets. Using a discrete phase model, the heat and momentum transfer of Ni/Al/C (2 wt.% diamond) composite powders (30–110 µm) within the plasma jet were simulated. Results show that particle characteristics, such as temperature and oxidation, can be controlled by adjusting plasma jet temperature (T∞) and velocity (U∞). Smaller particles heat faster, reaching higher temperatures with increased evaporation and oxidation rates. The modified nozzle enables Ni-based alloy particles to reach ~2500 °C, reducing oxygen inclusion in the plasma jet core. This setup allows for the control of the onset of carbon and oxygen reactions, wherein carbon serves as a sacrificial element, protecting the base alloy elements (such as aluminum) from excessive oxidation.

Key words: discrete phase modeling (DPM); in-flight oxidation; in-flight evaporation; atmospheric plasma spraying (APS); sacrificial elements; oxidation protection

Originally published at Plasma (Volume 8, Issue 1, Janurary 13 2025)

By Mahrukh Mahrukh, Sen-Hui Liu, Li Zhang, Sohail Husnain, Cheng-Chung Yang, Xiao-Tao Luo, and Chang-Jiu Li