November 10, 2025

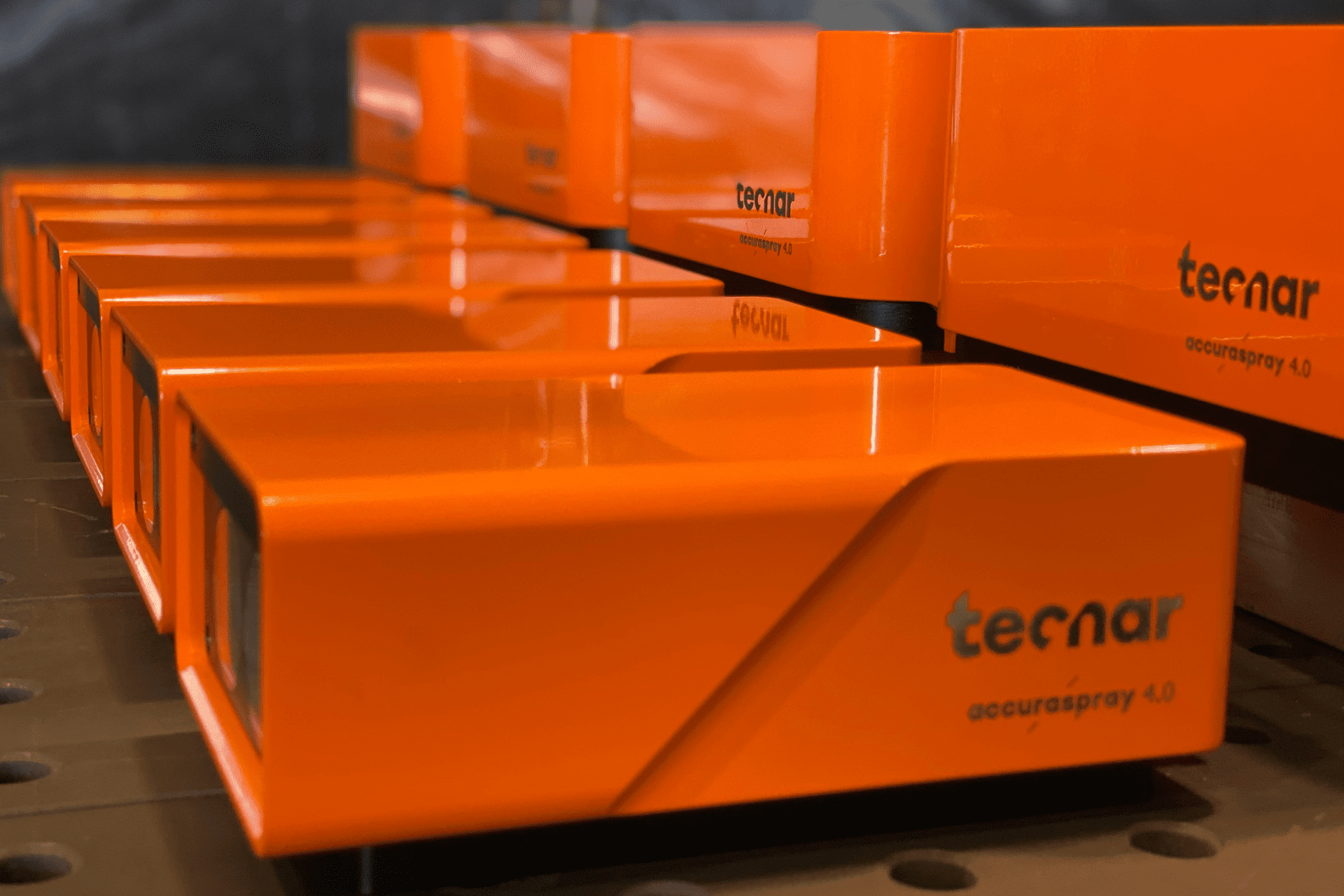

Analysis and optimization of TBC coatings on turbine blades through the use of the Accuraspray 4.0 sensor

(Translated from Italian) The quality of Thermal Barrier Coatings (TBC) used on turbine blades is crucial to ensuring the reliability and efficiency of turbines. The most commonly used deposition techniques for these coatings are Thermal Spray processes, particularly High Velocity Oxygen Fuel (HVOF) and Atmospheric Plasma Spray (APS). The primary objective of this thesis is to optimize HVOF and APS deposition processes through an innovative approach that involves real-time monitoring of process parameters using the Accuraspray 4.0 sensor. This instrument can measure particle beam characteristics (temperature, velocity, size, and intensity) with high precision, allowing these measurements to be correlated with the final coating properties. The work was conducted at ATLA Srl with the aim of increasing process repeatability, improving product quality, and optimizing the process. The methodological approach involved the creation of test specimens composed of a nickel superalloy plate (Hastelloy X), on which layers of bond coat and top coat were deposited using the HVOF and APS techniques. During deposition, the Accuraspray sensor monitored the spray parameters in real time, allowing for the identification of any instabilities and the collection of key data for subsequent statistical analysis. The core of the analysis is based on a multifactorial approach known as Design of Experiments (DoE), which allows for the simultaneous modification of multiple process variables and the assessment of their impact on the finished product. The data obtained were processed using ANOVA (Analysis of Variance), a statistical technique that allows for the determination of the significance of factors and their interactions, measured by the p-value. For the HVOF technique, the consolidated parameters used by the company produced a conformal coating, but it was observed that a reduction in oxygen flow, while maintaining the coating’s performance unchanged, could represent an economic advantage for the company. Regarding the APS technique applied to the bond coat, the aim was to reduce the amount of powder used to achieve a better compromise between quality and process costs. The ceramic top coat was applied via APS, using a yttrium-stabilized zirconia powder. The resulting coating showed a homogeneous distribution of pores and the absence of cracks or discontinuities, and the analysis confirmed the standard parameters as optimal for the process. Overall, the results highlight how the same parameter can have different effects depending on the type of coating (bond coat or top coat) or the technique used (HVOF or APS), due to the different nature of the materials and the operating ranges adopted.The Accuraspray sensor has proven useful for routine inspection, offering valuable support in process diagnosis and monitoring. However, it has become clear that the sensor’s measurements must be supplemented with microscopic analysis and statistical evaluations,as they alone do not guarantee the coating’s functional compliance.

Link to publication (in Italian)

Originally published at Polytechnic University of Turin, 2025

By Roberta Montana Lampo with supervisors Sara Biamino and Riccardo Mantoan