February 9, 2026

Impact of Nozzle Injection Angle on Flow Characteristics in Cold Spray Process for Hastelloy X Superalloy Powder

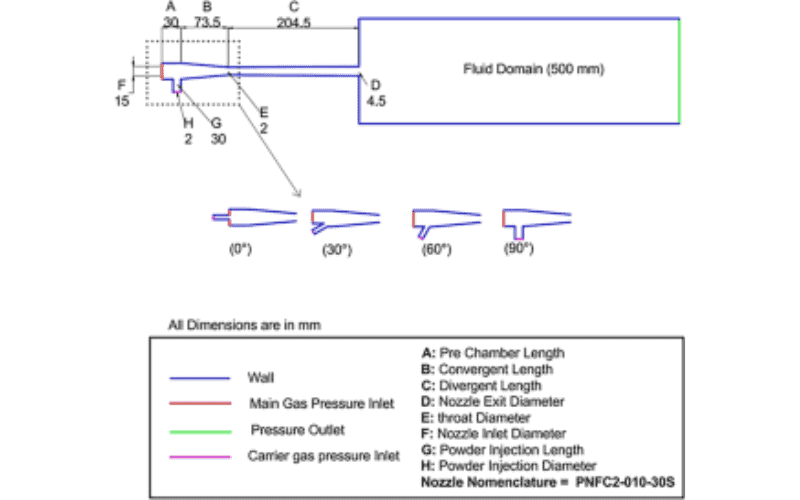

Hastelloy X exhibits excellent high-temperature strength and oxidation resistance, making it suitable for applications like including nuclear reactors, jet engines, and gas turbine engines. Conventional thermal spray techniques can induce thermal stresses, phase changes, and oxidation in Hastelloy X deposits. Cold spray is a solid-state technique that enables the deposition of dense, oxide-free coatings while maintaining the alloy’s original microstructure. This numerical study investigates the impact of various powder injection angles (0°, 30°, 60°, and 90°) on the cold spray process for Hastelloy X superalloy powder. Using computational fluid dynamics (CFD), we analyze particle velocity and flow characteristics to identify the optimal injection angle. The selected turbulence model, k-ω SST, effectively characterizes turbulent flows, making it suitable for elucidating the dynamics of gas-particle interactions. Complex flow structures, including Mach diamonds and shock waves, were observed, creating alternating pressure and velocity fields that significantly affect particle momentum transfer. Among all cases, the 30° injection angle achieved the highest particle velocity and the most focused particle stream, enabling more efficient entrainment and mixing. It also showed the most focused particle stream. Experimental validation using Accuraspray CS recorded an in-flight particle velocity of 710 ± 20 m/s 30° powder injection angle, in good agreement with the CFD-predicted 765 m/s. Microstructural analysis of deposited coatings revealed dense Hastelloy X layers with low porosity (0.70% ± 0.02%) and high deposition efficiency (92%). These results demonstrate that injection-angle optimization is critical for achieving superior particle acceleration and coating quality in cold spray of Ni-based superalloys.

Originally published at Journal of Thermal Spray Technology (08 January 2026)

By Sukhwinder Singh, Lopamudra Palodhi, and Harpreet Singh