September 11, 2025

Influence Of Process Parameters On The Microstructure And Adhesion Of Glaze-Based Coatings

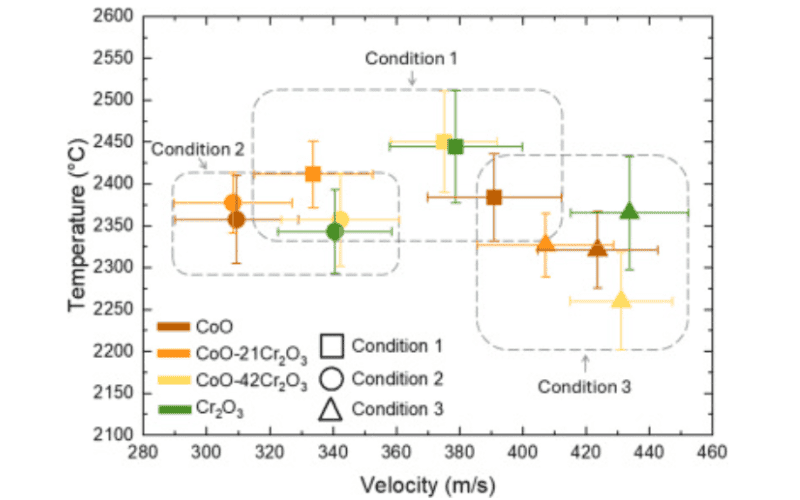

Developing coatings for specific applications involves several challenges, including the formation of defects and undesired chemical reactions during spraying, both of which pose significant engineering difficulties. Building on initial results in the development of glaze-based coatings, this study aims to provide insights into the effects of process parameters on the microstructure of coatings deposited via suspension plasma spray (SPS). These coatings were designed to mimic the glaze layer composition formed over cobalt-based alloys as a potential alternative to these materials. The influence of plasma current and spraying distance were analyzed for four different chemical compositions, and their impact on the coatings’ microstructure was assessed. The results revealed that CoO partially oxidized to Co₃O₄, as expected; however, a reduction to metallic cobalt also occurred, creating a unique layered pattern. Meanwhile, Cr₂O₃ exhibited minimal chemical reactivity. Additionally, shorter spraying distances led to the formation of undesirable cauliflower-like surface features, caused by the plasma drag forces. Under mixed chemical compositions, the coatings showed small amounts of spinel formation but primarily exhibited zones rich in either cobalt or chromium oxides. Scratch tests to evaluate the adhesion/cohesion indicated that metallic cobalt formation decreased coating cohesion, due to interlayer adhesion failure of the coating. Furthermore, the addition of chromium oxide improved coating cohesion and adhesion to the substrate.

Key words: Oxide-based coatings, Suspension plasma spray, Glaze layer, Wear, Gas turbine engines

Originally published at Surface and Coatings Technology (Volume 513, 1 October 2025, 132545)

By Andre R. Mayer, Bruno C.N.M. de Castilho, Amit Roy, Fadhel B. Ettouil, Christian Moreau, Pantcho P. Stoyanov b