January 7, 2026

Investigation of the Process Stability and Effectiveness Using a Multi-Arc Spraying Torch with Axial Suspension Injection

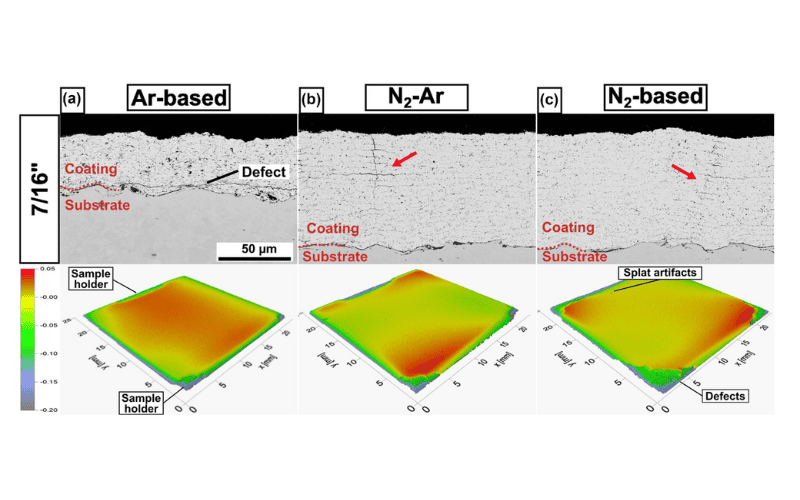

The Axial III TM torch is a multi-arc plasma generator equipped with three single cathode–anode units. It is widely used for suspension plasma spraying because of its axial feedstock injection. Previous work has shown that the plasma jet is not completely homogeneous, due top ower fluctuations and the triple distribution of the plasma enthalpy. This could affect the stability and efficiency of the spraying process. Therefore, state-of-the-art process diagnostics were used to further characterize the process. The plasma characteristics were studied at three different compositions while spraying a 30% wt.% Y 2 O2 water-based suspension using two different nozzle geometries.Time-resolved measurements of voltages and currents were used to gain insight into the arc dynamics and the plasma-suspension interaction. The resulting in-flight particle temperatures and velocities were analyzed using the Accuraspray 4.0. The specific plasma gas composition, particularly the nitrogen content, affected the temperature and transport coefficients of the plasma and thus the par-ticle characteristics. These factors, in turn, directly affected the deposition efficiency and the microstructure of the resulting coatings, as demonstrated by the experiments. Meanwhile, the overall process efficiency decreased for the nozzle with the reduced expansion ratio. This study pro-vides the basis for deriving measures to improve the stability and efficiency of suspension plasma spraying.

Key words: particle diagnostic, process effectiveness, process stability, suspension plasma spray, thermal spray

Originally published at Journal of Thermal Spray Technology (28 October 2025)

By J. Schmitt, S. Zimmermann, C. Kirner, R. Vaßen, J. Schein, and G. Mauer