March 6, 2025

Repair of Single-Crystal CMSX-4 Using the High Velocity Air Fuel Process

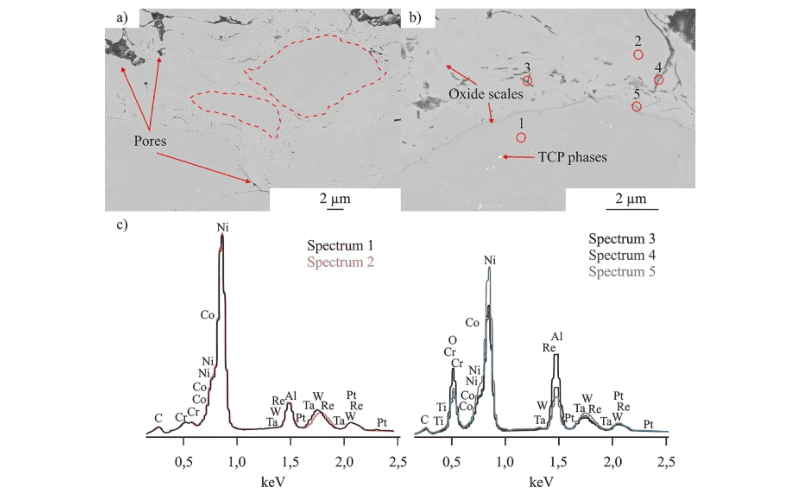

Turbine blades in aircraft engines and land-based gas turbines are exposed to harsh environmental conditions that make them susceptible to degradation mechanisms, such as creep, oxidation, and fatigue damage. Therefore, research into effective repair methods is of high importance, especially for single crystal components, as they are cost-intensive to produce. The HVAF process is suitable for repair applications as it can produce dense layers with low oxygen content, which are essential for the repaired area. Additionally, the fine grain structure is advantageous for the subsequent directional recrystallization planned in future studies, aiming to transform the repair layer into a columnar or even single-crystal structure. This study focuses on applying CMSX-4 powder to single crystal substrates of similar composition using High Velocity Air Fuel Spraying (HVAF). Specifically, the effects of powder particle size, nozzle configuration, and various other process parameters, such as spray distance and carrier gas flow, on the characteristics of HVAF-deposited CMSX-4 were investigated. The microstructure was examined by scanning electron microscopy. Particle velocity and temperature measurements were performed to enhance comprehension of the process.

Key words: accura spray, high velocity air fuel spraying, parameter influence, particle temperature and velocity measurements, repair process, single crystal CMSX-4, single splat

Originally published at Journal of Thermal Spray Technology (February 24, 2025)

By M. Létang, S. Björklund, S. Joshi, D. Sebold, O. Guillon and R. Vaßen