October 22, 2025

Simulation and Experimental Validation of Splat Profiles for Cold-Sprayed CP-Ti with Varied Powder Morphology

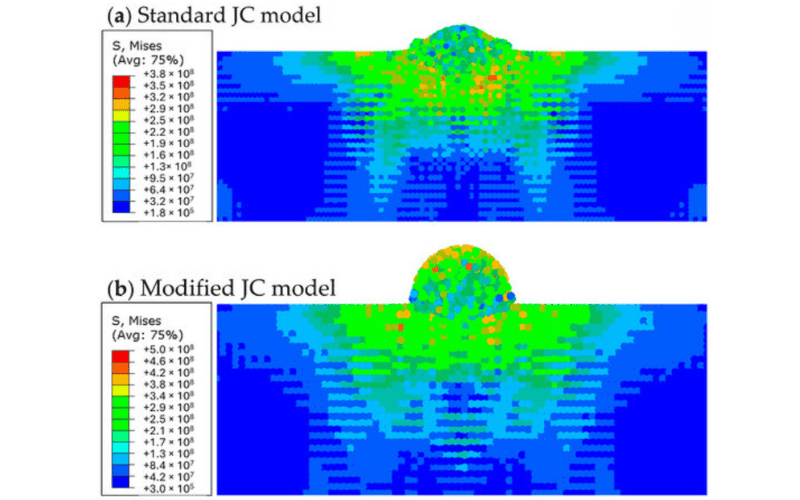

The cold spray (CS) process has gained momentum as an additive manufacturing technology, due to its low processing temperatures. Computational modelling can accompany CS experiments to optimise deposition parameters, as well as predict coating properties and their final performance. A commonly used plasticity model is the Johnson–Cook (JC) model; however, its accuracy is limited at the high strain rates typical of cold spray. This study aims to assess the robustness of predictions using a modified JC model, particularly for two material systems of commercially pure titanium (CP-Ti) and Al6061-T6, and feedstock powders of two sizes and three morphologies. CP-Ti powders of spherical and irregular morphologies were sprayed onto CP-Ti substrates using a Titomic TKF1000 cold spray system. The cross-sectional splat profiles and flattening ratios were compared against smoothed particle hydrodynamics (SPH) simulations. The deposition process of particles was simulated using a modified JC model, implemented as an ABAQUS (2020) VUHARD user subroutine programme. The results showed that SPH simulations predicted the depth of impact, the splat profiles and the flattening ratios. Additionally, the simulations indicated that the impacting particle temperature remained below the melting point of CP-Ti throughout the process. Lastly, it was demonstrated that the irregular CP-Ti feedstock showed greater tendency of restitution than spherical feedstock.

Key words: cold spray; simulation; modified Johnson–Cook; feedstock morphology; CP-Ti

Originally published at Applied Mechanics (Volume 6, Issue 2, Janurary 13 2025)

By Wesley Kean Wah Tai, Martin Eberle, Samuel Pinches, Shareen S. L. Chan, Rohan Chakrabarty, Max Osborne, Daren Peng, Rhys Jones, and Andrew S. M. Ang