September 15, 2005

Superior Performance of High-Velocity Oxyfuel-Sprayed Nanostructured TiO2 in Comparison to Air Plasma-Sprayed Conventional Al2O3-13TiO2

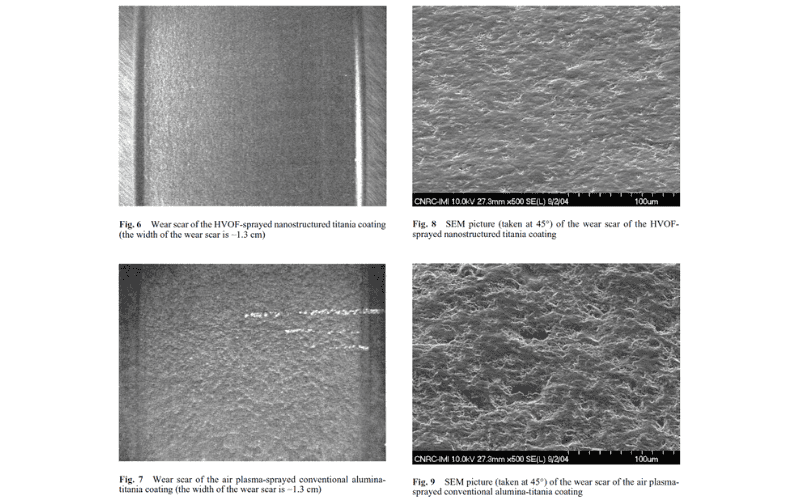

Air plasma-sprayed conventional alumina-titania (Al2O3-13wt.%TiO2) coatings have been used for many years in the thermal spray industry for antiwear applications, mainly in the paper, printing, and textile industries. This work proposes an alternative to the traditional air plasma spraying of conventional aluminatitania by high-velocity oxyfuel (HVOF) spraying of nanostructured titania (TiO2). The microstructure, porosity, hardness (HV 300 g), crack propagation resistance, abrasion behavior (ASTM G65), and wear scar characteristics of these two types of coatings were analyzed and compared. The HVOF-sprayed nanostructured titania coating is nearly pore-free and exhibits higher wear resistance when compared with the air plasma-sprayed conventional alumina-titania coating. The nanozones in the nanostructured coating act as crack arresters, enhancing its toughness. By comparing the wear scar of both coatings (via SEM, stereoscope microscopy, and roughness measurements), it is observed that the wear scar of the HVOF-sprayed nanostructured titania is very smooth, indicating plastic deformation characteristics, whereas the wear scar of the air plasma-sprayed alumina-titania coating is very rough and fractured. This is considered to be an indication of a superior machinability of the nanostructured coating.

Key words: abrasion resistance, air plasma spray, conventional alumina-titania, high-velocity oxyfuel, nanostructured titania

Originally published at Journal of Thermal Spray Technology (September 2005, Volume 14, pages 397–404, 2005)

By R. S. Lima, B. R. Marple