January 4, 2024

Using optical emission spectroscopy in atmospheric conditions to track the inflight reduction of plasma sprayed TiO2−x feedstock for thermoelectric applications

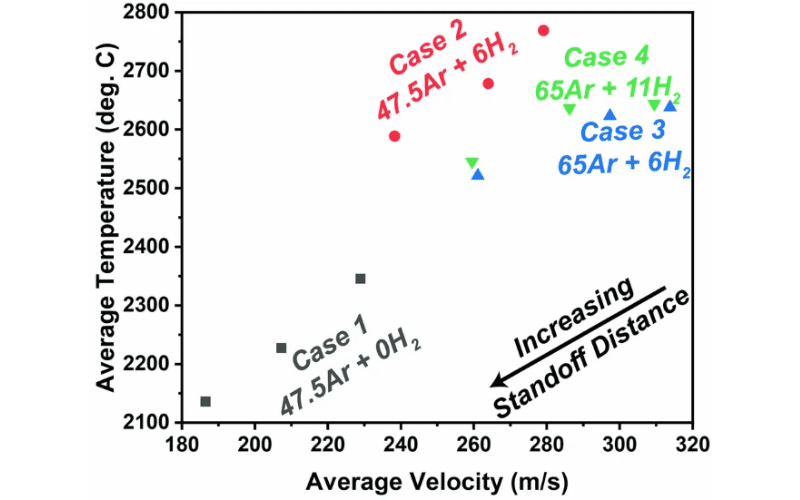

Thermal spray deposition (specifically Atmospheric Plasma Spraying, APS) is a well-established surface coating technology with a broad scope of applications (i.e., insulative coatings, tribological coatings, anti-corrosion coatings, etc.). In addition, there is a constant drive to introduce the APS process into new and emerging fields. One such niche application for APS would be sub-stoichiometric TiO2−x coatings with enhanced thermoelectric performance (compared to the bulk material). The APS process in this context has a unique ability—given the use of hydrogen as a plasma gas—to reduce TiO2−x material during processing. However, to this point, there is neither a reliable nor self-consistent method to assess (nor control by parametric optimization) the inflight reduction of molten oxide particles during processing. This study shows that using Optical Emission Spectroscopy (OES), it can be possible—even in atmospheric conditions—to identify characteristic emission peaks associated with the inflight reduction of TiO2 during APS. Using this OES data, the input spray processing parameters and their influence on coating microstructure and the degree of inflight reduction of the material will be shown. Results suggest under equilibrium conditions only a minimal amount of hydrogen gas is needed in the plasma to fulfill the TiO2 reduction.

Originally published at Scientific Reports (Volume 14, article number 554, 2024)

By Georg Mauer, Edward J. Gildersleeve V